NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

Qin-Tech CCS Production Line: Efficient Assembly, One-Stop Solution

Category: Industry information

Date: 2024-09-18

Click: 853

Collection:

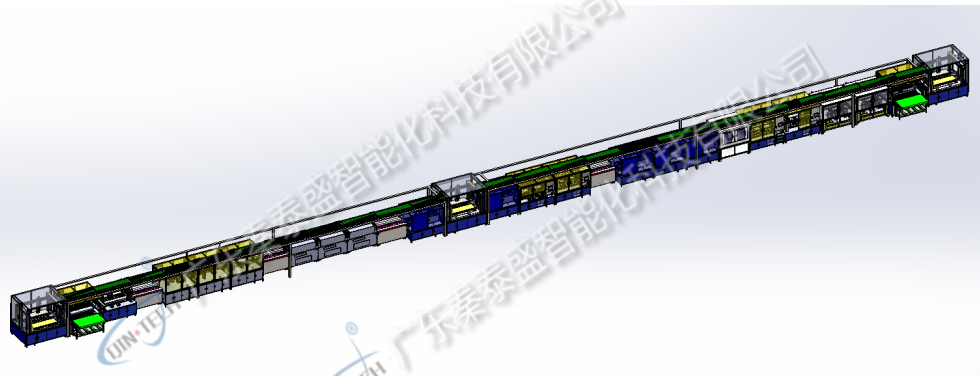

Qin-Tech CCS Production Line: Efficient Assembly, One-Stop Solution

Qin-Tech’s CCS production assembly lines are designed to embody a high degree of automation and precise control to meet the demands of high-precision assembly and manufacturing. Below is some analysis of the provided production line features:

1、High precision visual positioning The vision positioning accuracy reaches plus or minus 0.01mm, which means that the products or components to be processed can be accurately identified and positioned by the machine vision system during the production process, ensuring that every step of the operation is precise and error-free.

2、High-precision carrier handling The running accuracy of the carrier handling mechanism is +0.05mm, which ensures the stability and accuracy of the products when moving in the production line and prevents excessive displacement or tilting during the handling process.

3、Automation process The production line has a variety of automation functions, such as automatic reflow cycle, automatic centralized board loading, automatic two-dimensional code labeling, automatic hot pressing of the patch point, automatic electrical testing, automatic bending, automatic loading of blister trays and automatic distribution of defective products, and so on. These functions greatly reduce the need for manual intervention, improve production efficiency, reduce production costs, and ensure the stability of product quality.

4、Efficiency and flexibility The introduction of automated production lines reduces errors and delays caused by human factors and increases production efficiency and output. At the same time, by flexibly adjusting the configuration of the production line and the process flow, it can quickly adapt to different production demands and product changes.

5、Quality control Functions such as automated inspection (e.g. automatic electrical testing) and automatic sorting of defective products ensure strict control of product quality. Any product that does not meet quality standards can be detected and separated in time, thus reducing the risk of non-conforming products entering the market.

6、Sustainability Through automated production, companies can reduce their dependence on human resources and reduce labor costs. At the same time, as the stability and accuracy of the production process are improved, material waste and energy consumption are reduced, which is conducive to the sustainable development of the enterprise.

To summarize, the design of the Qin-Tech CCS production and assembly line reflects a high degree of automation, precision, and flexibility. Such a production line is significant for improving product quality, increasing production efficiency, reducing production costs, and enhancing enterprise competitiveness.

|