CASES

Contact Us Mobile: +86 139 2686 8913 Tel: +86 769 8166 4889 Fax:0769-8535 6530 Online QQ:1552701665 E-mail:sale11@in-techgroup.com Company website:www.qin-tech.com Company address: No. 6, Lianhu Road, Xianxi Community, Chang'an Town, Dongguan City

|

Water treatment industry

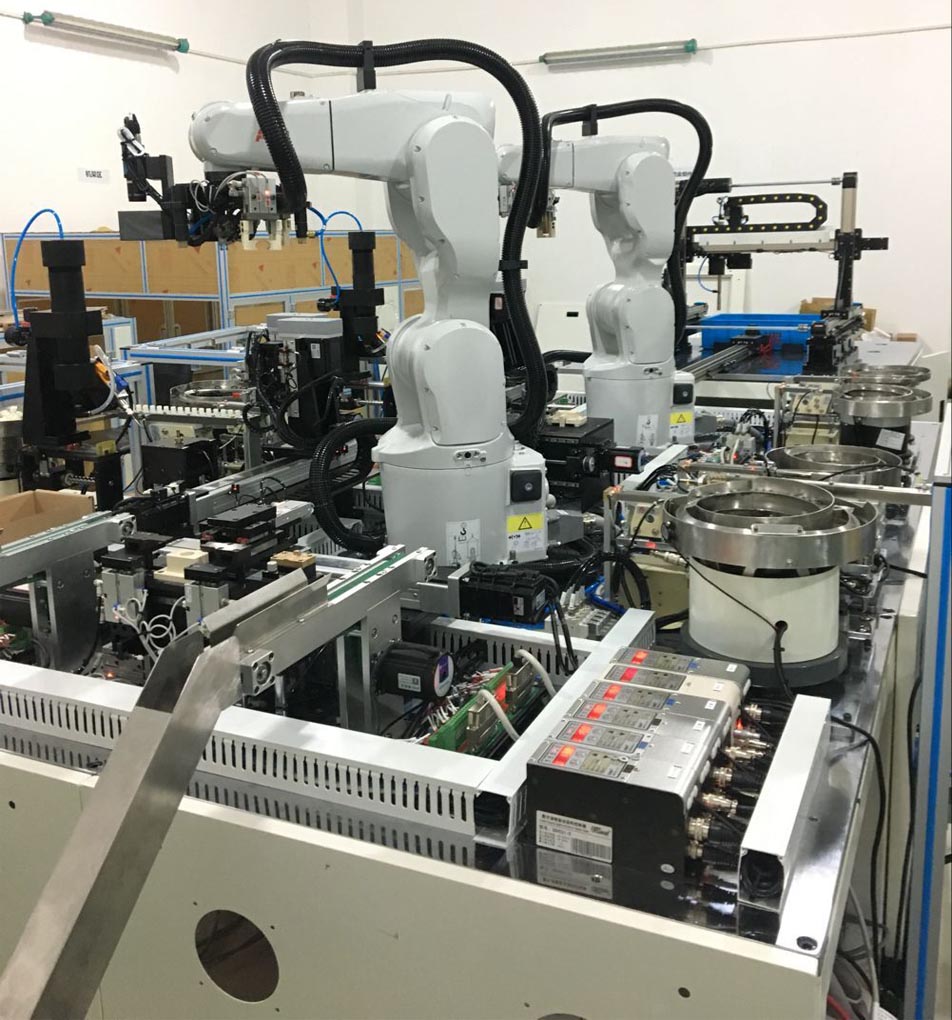

Pressure rod assembly automatic production line: The automated production line is designed by two 6-axis robots, a press-bar component feeder, 9 vibrating discs, 5 sets of modules, 4 sets of multi-axis linear modules, and three sets of CCD vision. Assembling 10 kinds of materials together, three sets of vision systems monitor components, semi-finished products and finished products to prevent wrong installation and missing installation, the software with independent software copyright monitors the entire production and connects with the customer's MES system in real time to ensure quality. control and traceability.

Fully automated valve body assembly line for the water treatment industry: 1. It has the ability of fully automatic production of 65HE valve body soft water and water mixing components assembly (mainly for 65 series valves, and further extended to 85 series control valves); 2. The function of quick line change is realized by replacing the product fixture, and the ability of personnel to add materials at 2-hour intervals; 3. All stations are equipped with sensors, CCD or pressure sensors to monitor each assembly station, and the MES system is connected to record production information and abnormal problems; 4. Humanized software and hardware design, front-line workers can take jobs after simple training; 5. Safety protection devices must be installed within the range of motion of all moving bodies. For equipment that has the risk of being pinched by employees, it is necessary to use a design that starts with both hands, and the software will alarm in time if there is an abnormality, and make relevant records; 6. The working position on the production equipment for personnel to work should be safe and reliable, and the working space should ensure that the operator has room to move, and the design should leave enough space for escape; 7. A protective cover or protective design is installed for each motorized device or components with potential safety hazards.

|