CASES

Contact Us Mobile: +86 139 2686 8913 Tel: +86 769 8166 4889 Fax:0769-8535 6530 Online QQ:1552701665 E-mail:sale11@in-techgroup.com Company website:www.qin-tech.com Company address: No. 6, Lianhu Road, Xianxi Community, Chang'an Town, Dongguan City

|

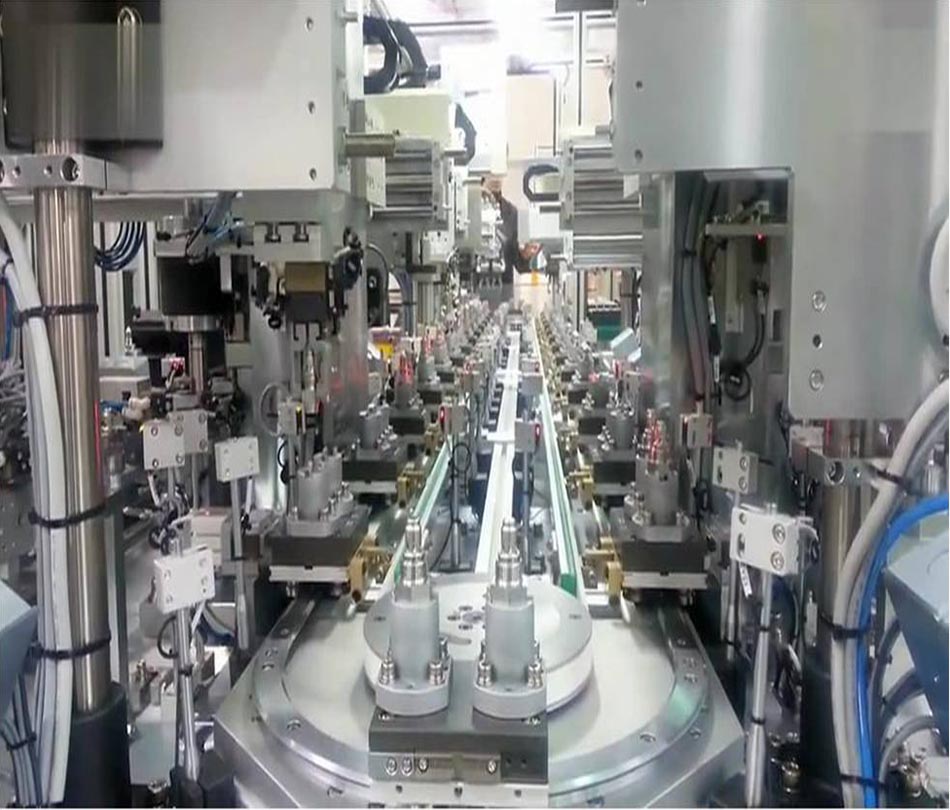

Consumer Electronics Industry

Fully automatic electrical switch assembly line: 1. The equipment uses automatic equipment for electrical switch assembly; 2. The equipment carrier is a 1-out 12-assembly structure, which can complete 12 product assembly at the same time; 3. Touch screen control, parameter setting, output calculation; 4. Equipped with SMEMA interface to communicate with other equipment, with data monitoring and statistical output, equipment failure information and automatic rejection system; 5. The UPH of the equipment is about 2600PCS/H; 6. Failure alarm and shutdown, the operation is automatic mode; 7. The conveying vehicle is used for circulation transfer; 8. The output can be greatly increased while ensuring the reduction of personnel; the product quality and yield will also be higher.

Audio automatic assembly and test line: 1. Audio automatic assembly, can automatically assemble all parts on the bottom case, automatically lock the speaker, automatically install the fixed seat, automatically twist the subwoofer, automatically install the shell, automatically lock the panel, automatically install the handle, automatically install the handle, automatically install Automatically install pulleys, etc. Can adapt to different sizes of speakers. 2. Using a special locking module, the deep hole 150mm can also be locked; the XYZ three-axis plus the high-torque R-axis quickly and accurately grabs and tightens the subwoofer. 3. The positioning jig adopts the up and down return method, and the rollers on both sides are driven. The positioning of the station jig adopts the taper pin lifting and precise alignment; the size of the jig can be universal.

Accessories automatic placement and appearance inspection line: Description: The assembly line is changed to our mature standard sticker glue machine combined with the accessories on the customer's mobile phone motherboard for process planning, and the last stop is the automatic appearance and accessories review machine to improve the inspection quality and efficiency. High efficiency: the same output can save 70% of personnel. High quality: Our self-adhesive machine has 5 years of mature customer experience and rich experience in non-label accessories. The equipment is stable and reliable to ensure product quality.

|