NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

How to deal with automobile waste power batteries?

Category: Industry information

Date: 2024-09-11

Click: 987

Collection:

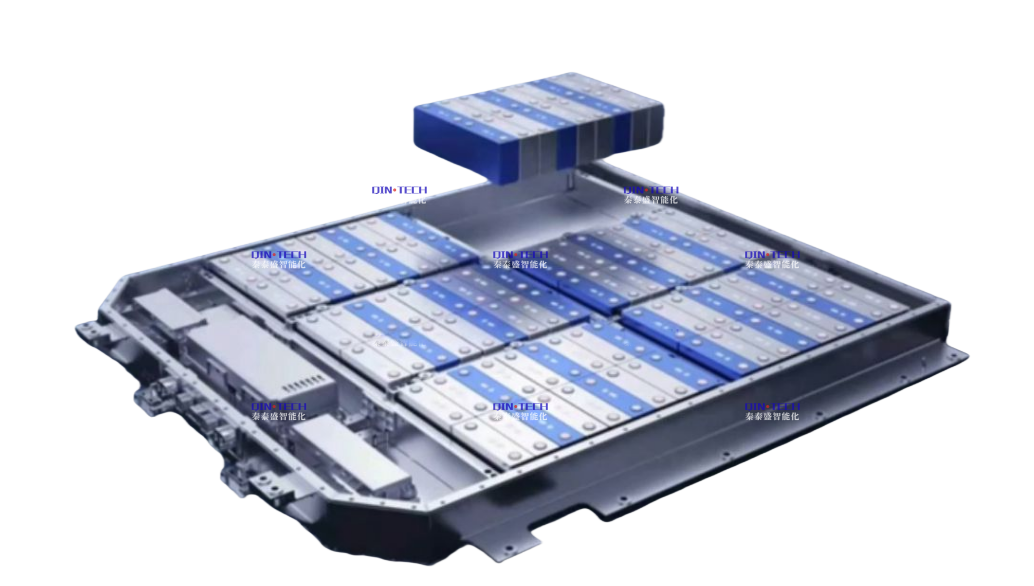

How to deal with automobile waste power batteries? China has become the world's largest producer and seller of new energy vehicles. With the rapid development of new energy vehicles, the number of used power batteries continues to increase. According to the forecast of the New Energy Battery Recycling Committee, by 2027, the cumulative decommissioning volume of power batteries will reach 1.14 million tons. 2020, the cumulative decommissioning volume of power batteries in China's new energy vehicles has reached 200,000 tons, and it is expected that in 2025, this figure will surge to 780,000 tons.

Waste power batteries, if not handled properly, can cause serious environmental pollution and waste of resources. Batteries contain heavy metals and harmful chemicals inside, and if improperly recycled into small workshops and improperly operated during the dismantling process, it will lead to environmental pollution, raise the PH value of the soil, and may also produce toxic gases when improperly handled. At the same time, waste power batteries still contain a large number of valuable metal materials, such as lithium, cobalt, nickel, and so on. Reasonable recycling and reuse of these metals can not only reduce the exploitation of new resources but also reduce production costs.

In addition, China's new energy private cars in the driving 600,000 kilometers or a driving time of about 5 to 8 years, it is recommended scrap, the operation of the car by small, medium, and large cars has a corresponding number of years of mandatory scrapping. According to industry estimates, the average retirement time of pure electric vehicles is 10.3 years. When the “retirement tide” of new energy vehicles arrives, how to deal with waste power batteries has become a new industry issue.

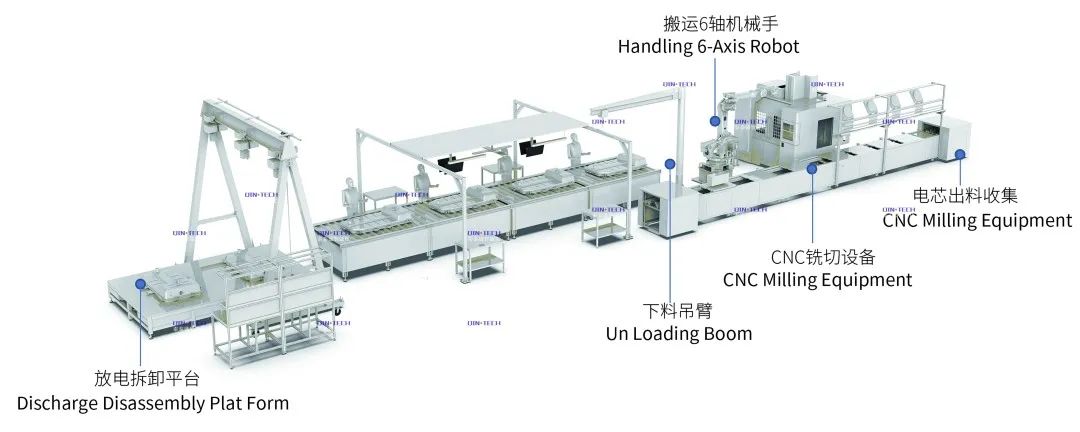

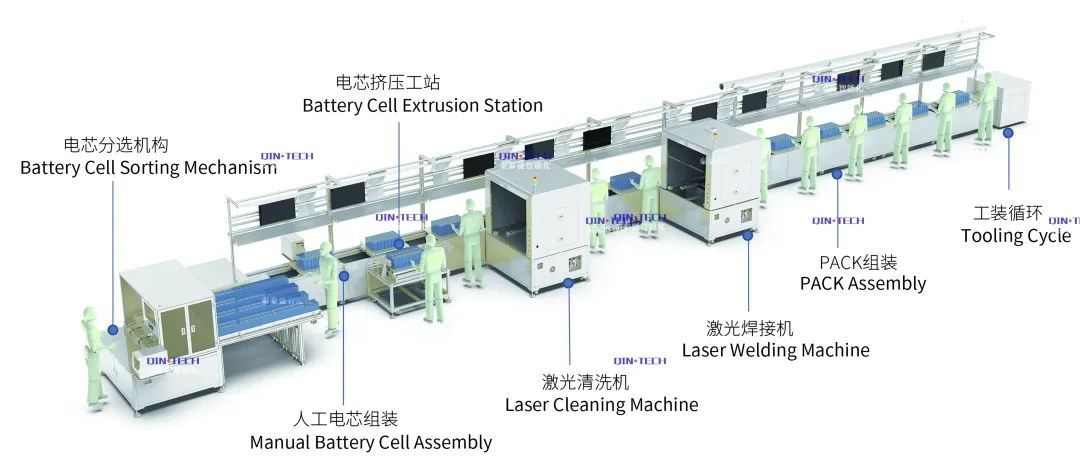

II. Main treatment methods (i) Laddering utilization Ladder utilization refers to the necessary inspection and testing, classification, splitting, battery repair, or reorganization of used power storage batteries into ladder products so that they can be applied to other fields, such as electric bicycles, energy storage batteries, and so on. With the rapid development of new energy vehicles, the amount of retired power batteries is increasing, and the laddering utilization provides new application scenarios for these retired batteries, realizing the effective use of resources. Guangdong Qin-Tech has launched two green production lines in the field of secondary utilization:

Production line features. (1) dismantling battery pack size compatible range: SUV, small cars, large buses, vans, and other types of chassis battery packs and general modules; (2) With servo programmable speed control function to meet the requirements of different material speed beats; (3) Variable frequency conveying speed adjustable, low-speed adjustable stop.

Production line features. (1)The production line can be compatible with assembly/module discharge detection; (2)The production line is highly automated, with less labor involved, which can greatly improve the production capacity of the line; (3)The production line monitors each process in real time, which makes it convenient to understand the specific status of each process intuitively.

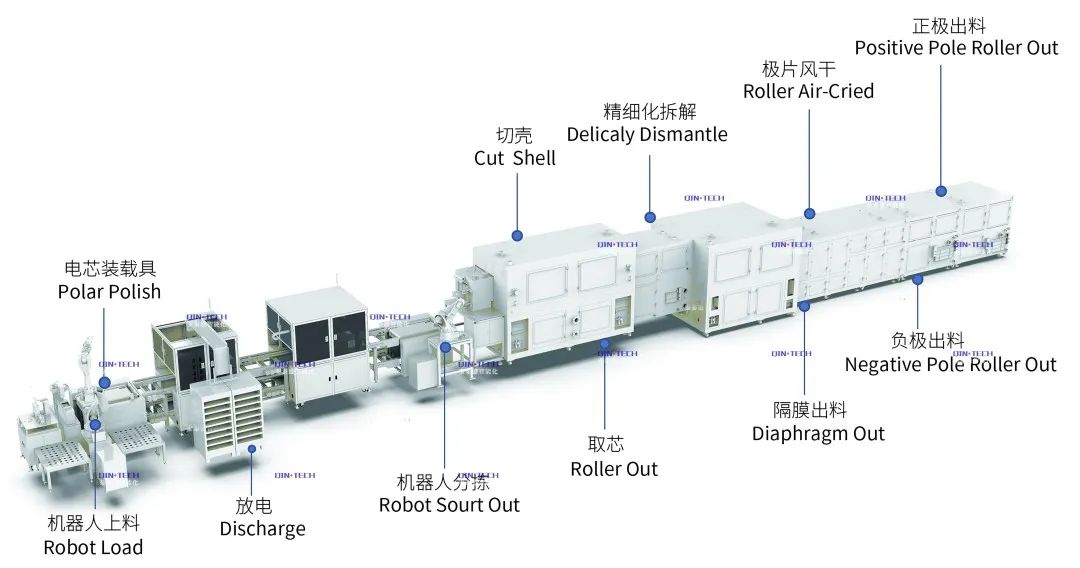

IV. Dismantling and regeneration Dismantling and regeneration is to dismantling, sorting, and smelting of used batteries after they are scrapped, to extract high-value metal elements to make new batteries. When power batteries cannot be utilized in a stepwise manner, dismantling and regeneration become important treatment methods. By dismantling used batteries, metal elements such as lithium, cobalt, and nickel can be extracted from them, and after smelting and other processes, they can be used to make new battery materials. Guangdong Qin-Tech has launched two green production lines in the field of fine dismantling:

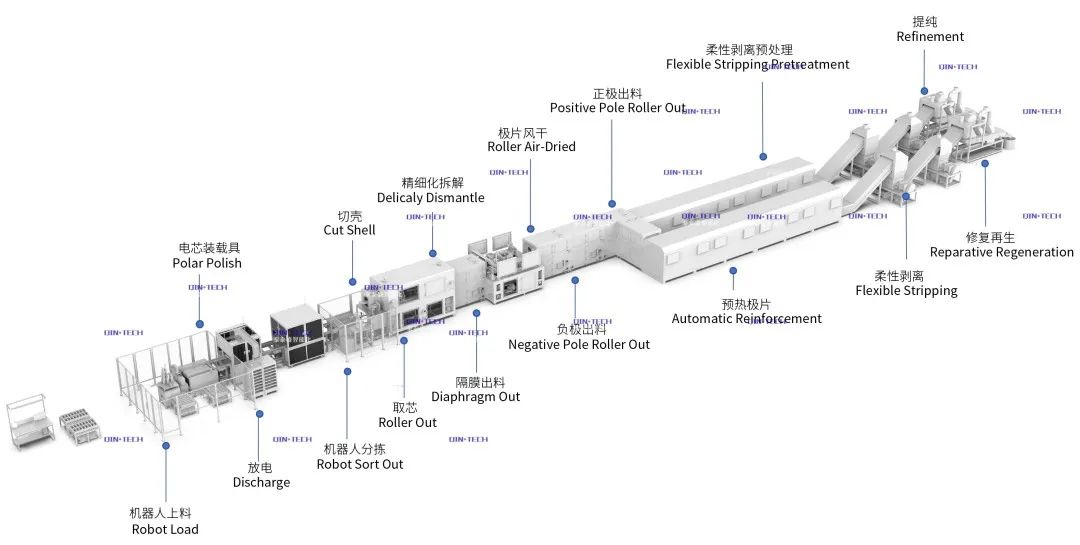

1、Cycle Method green recycling production line for waste power batteries production line-recycling pole piece production line Five advantages: (1) Subversive: Pure green technology, no pollution, in line with the global dual-carbon goal; (2) Pioneering: the earliest green recycling model implemented in the industry; (3) Intelligence: no artificial participation in the operation of the fully intelligent mode; (4) Environmental protection: The whole process adopts pure green technology (including material repair and regeneration & exhaust gas treatment); (5) Innovative: Innovative development of pole piece reuse & waste electricity reuse technology.

2、Cycle Method green recycling production line for waste power batteries-recycling powder production line Process advantages: (1) Intelligent extraction & recycling; (2) Multiple patented intelligent extraction technology can extract the 5 materials in the battery intelligently and accurately, and then obtain the battery-level positive and negative electrode materials through creative repair & regeneration technology; (3) short process, high efficiency; low energy consumption; no pollution; high economic efficiency; (4) The production line can automatically complete the battery conveying, positioning, dismantling, and recycling processes, reducing manual intervention and improving dismantling efficiency; (5) Closed operation is adopted in the dismantling process, which reduces the emission of fans and harmful gases, and at the same time, it can carry out harmless treatment of waste liquid and waste gas produced by dismantling.

Problems and challenges facing the industry Excessive battery models push up the cost of secondary utilization, unregulated enterprises disrupt market competition, and cause secondary pollution. China Electric Vehicle Association Secretary General and Chief Expert Zhang Yongwei proposed that the key to reuse is standards and regulations, and now also need to solve the problem of too many battery models. Too many models will push up the cost of secondary utilization, different brands, different batches of batteries in the material, performance, life, safety, energy density, and other aspects of variability, cylindrical, square, soft pack three shapes of batteries have their own strengths and weaknesses, resulting in increased detection and classification difficulties, secondary utilization of secondary group design costs and processing costs rise, hindering the industrialization of business.

Unstandardized and backward enterprises disrupt market competition and also cause further pollution, affecting the circular economy of resource regeneration. At present, the Ministry of Industry and Information Technology announced in line with the comprehensive utilization of waste power batteries industry norms and conditions of the whitelist of 156 companies, but the eye of the sky shows that the domestic power battery-related recycling enterprises registered more than 40,000. This means that many power battery recycling materials are currently being diverted by the informal market. These informal enterprises in the recycling process, often lack professional technology and equipment, operation is not standardized, may lead to heavy metals in the battery and organic electrolytes and other serious threats to the environment, such as the existence of cobalt, nickel, and other heavy metal pollution, fluorine pollution and white pollution caused by the battery diaphragm, while there is a waste of lithium, nickel, cobalt, and other high-value resources.

V. Future Prospects

Although the treatment of waste power batteries faces many problems, with the development of technology and policy improvement, the prospect is broad and worth looking forward to.

(i) Technological innovation to lead the future development

With the continuous progress of science and technology, power battery recycling technology will continue to innovate. In terms of gradient utilization, the future is expected to reduce costs and improve product quality and market acceptance through more advanced testing technology and intelligent pair restructuring systems. In terms of dismantling and regeneration, new bio-recycling technology will also gradually mature, and the development of automated dismantling and material sorting technology will improve dismantling efficiency and fineness, reduce the risk of manual operation, reduce the mixing of impurities, and improve the metal recovery rate.

(ii) Policy support to promote the standardized development of the industry

The government will further strengthen the policy support and supervision of the waste power battery recycling industry. Improve the relevant laws and regulations, clarify the responsibility of the main body of each link, standardize the recycling process, and crack down on illegal recycling and processing behavior. Increase support for formal recycling enterprises, give financial subsidies and tax incentives, and encourage enterprises to increase investment in technology research and development. Establish a sound evaluation and testing system for retired power batteries, formulate unified standards and norms, raise the threshold of industry access, and promote orderly market competition.

(iii) industry chain cooperation to achieve a win-win situation

In the future, the power battery recycling industry chain links will strengthen cooperation to achieve win-win development. Battery manufacturers, vehicle manufacturers, recycling companies, and material companies will establish a closer cooperative relationship to jointly build a perfect recycling system. Battery manufacturers and vehicle manufacturers can incorporate the recycling and treatment of used batteries into their corporate development strategies, and cooperate with recycling companies to ensure standardized recycling and treatment of used batteries. Recycling enterprises can improve the metal recovery rate, reduce production costs, and realize the recycling of resources through cooperation with material enterprises.

(iv) Continuous expansion of market scale, bright prospects for the industry

With the continuous growth of the new energy vehicle market and the increasing amount of power battery decommissioning, the waste power battery recycling market scale will continue to expand. It is expected that by 2025, China's decommissioned power batteries will reach 780,000 tons, the battery recycling industry market size is expected to reach 50 billion yuan; by 2030, China's decommissioned power batteries will be more than 1.5 million tons, the battery recycling industry market size will be more than 100 billion yuan.

Driven by the “double carbon” goal, the power battery recycling industry will develop in a more environmentally friendly, green, and efficient direction. More and more enterprises will be involved in this “hundred billion” track, through technological innovation, policy support, and industry chain cooperation, to achieve sustainable development of the industry. In the future, the waste power battery recycling industry will become an important support for the new energy automobile industry, contributing to the green transformation and sustainable development of China's economy. |