Category: Technical support

Date: 2024-09-10

Click: 348

Author: 秦泰盛

Collection:

New energy battery pack cell thermal insulation cotton and aerogel thermal insulation cotton line laminating equipment introduction

As we all know, new energy vehicles are mainly driven by electricity. Most of the fire and explosion incidents of new energy vehicles that we see on the Internet are due to the thermal runaway of lithium batteries after internal or external short circuits, which release a large amount of heat in a short period, and the temperature rises sharply. The flammable liquid electrolyte is ignited at high temperatures, which triggers the battery fire. Through thermal diffusion, a single thermal runaway battery triggers thermal runaway in neighboring batteries through heat conduction and flame, resulting in the thermal runaway of the entire battery module or pack, which triggers a fire and explosion event.

In response to this problem, smart entrepreneurs have produced aerogel thermal insulation cotton to solve it. Aerogel thermal insulation cotton is characterized by low thermal conductivity, good heat preservation, Class A fireproofing, and lightweight. Therefore, this aerogel insulation cotton is mostly used in the insulation buffer between the electric cells of new energy battery packs.

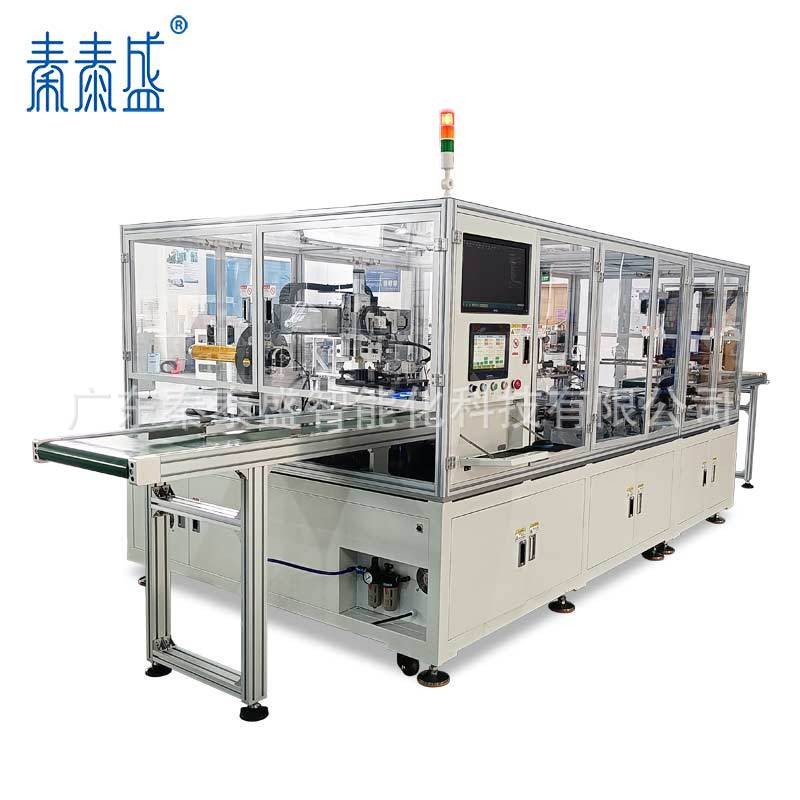

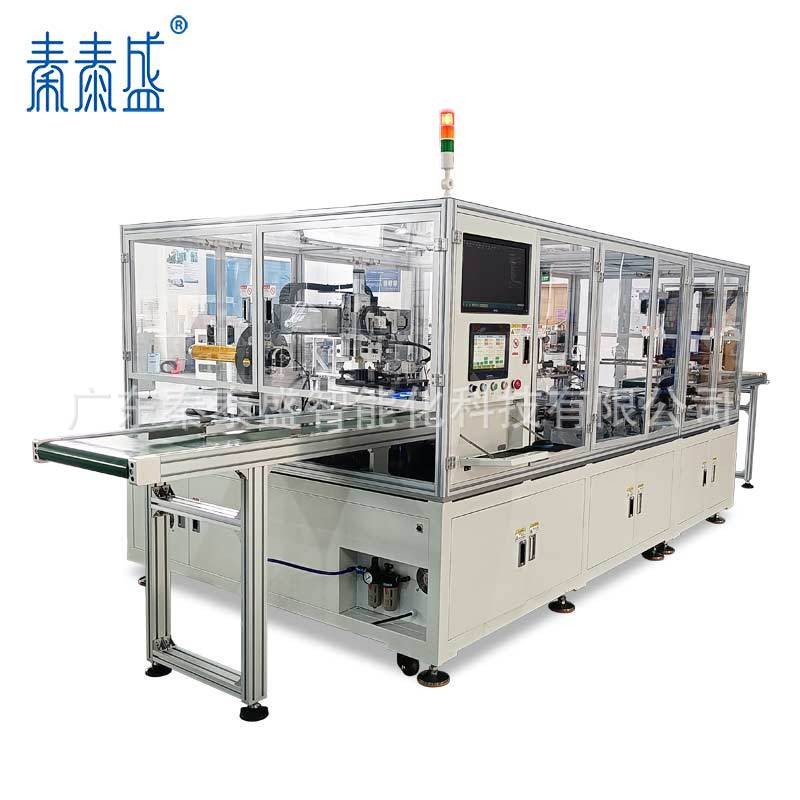

In recent years, under the support of various favorable policies, the new energy automobile industry has been vigorously developed, and the production volume of aerogel insulation foam is also increasing yearly. Therefore, many production enterprises can improve the production capacity within a unit of time but also have set up automated equipment production workshops. Today, I would like to introduce you to a Qin-Tech production that is more popular with customers with aerogel insulation cotton line laminating equipment.

This aerogel insulation cotton line laminating equipment introduction:

1. Docking customer other equipment automatic feeding, compact design equipment covers an area of small;

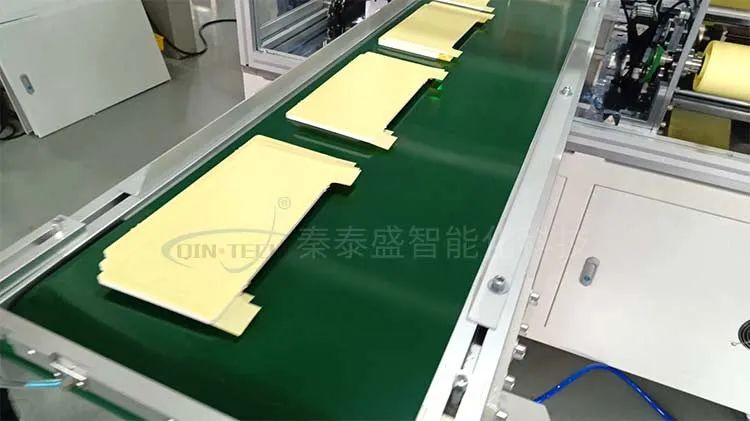

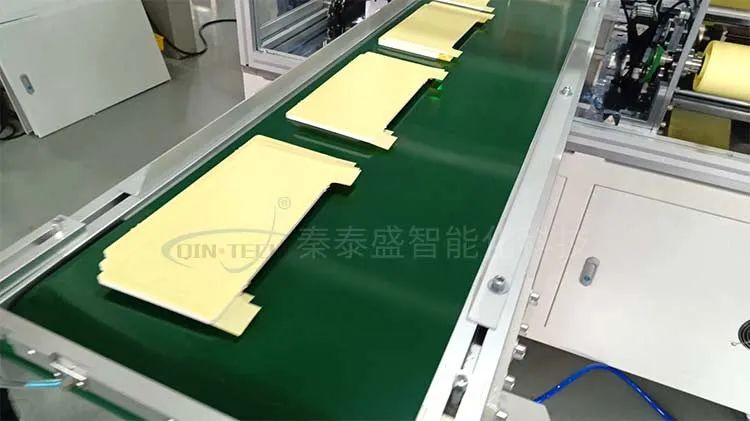

2. The equipment is divided into two sections before and after the module, the front section of the equipment pastes heat insulation cotton front double-sided adhesive; the back-end equipment pastes the reverse side of the double-sided adhesive and the pressure of the release paper tearing hand, pre-tear the release paper, the second flattening of the release paper, automatic discharging;

3. Independent control system for both front and rear equipment;

4. The equipment products can be compatible with large sizes: maximum 250 * 250mm, minimum 80 * 80mm;

5. The equipment has two sets of high-precision CCD used to ensure that the double-sided adhesive mounting accuracy, can be ± 0.2mm repeat mounting accuracy;

6. Optional automatic strapping machine to achieve automatic strapping and packaging, enhance the efficiency of manual work and reduce labor.