NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

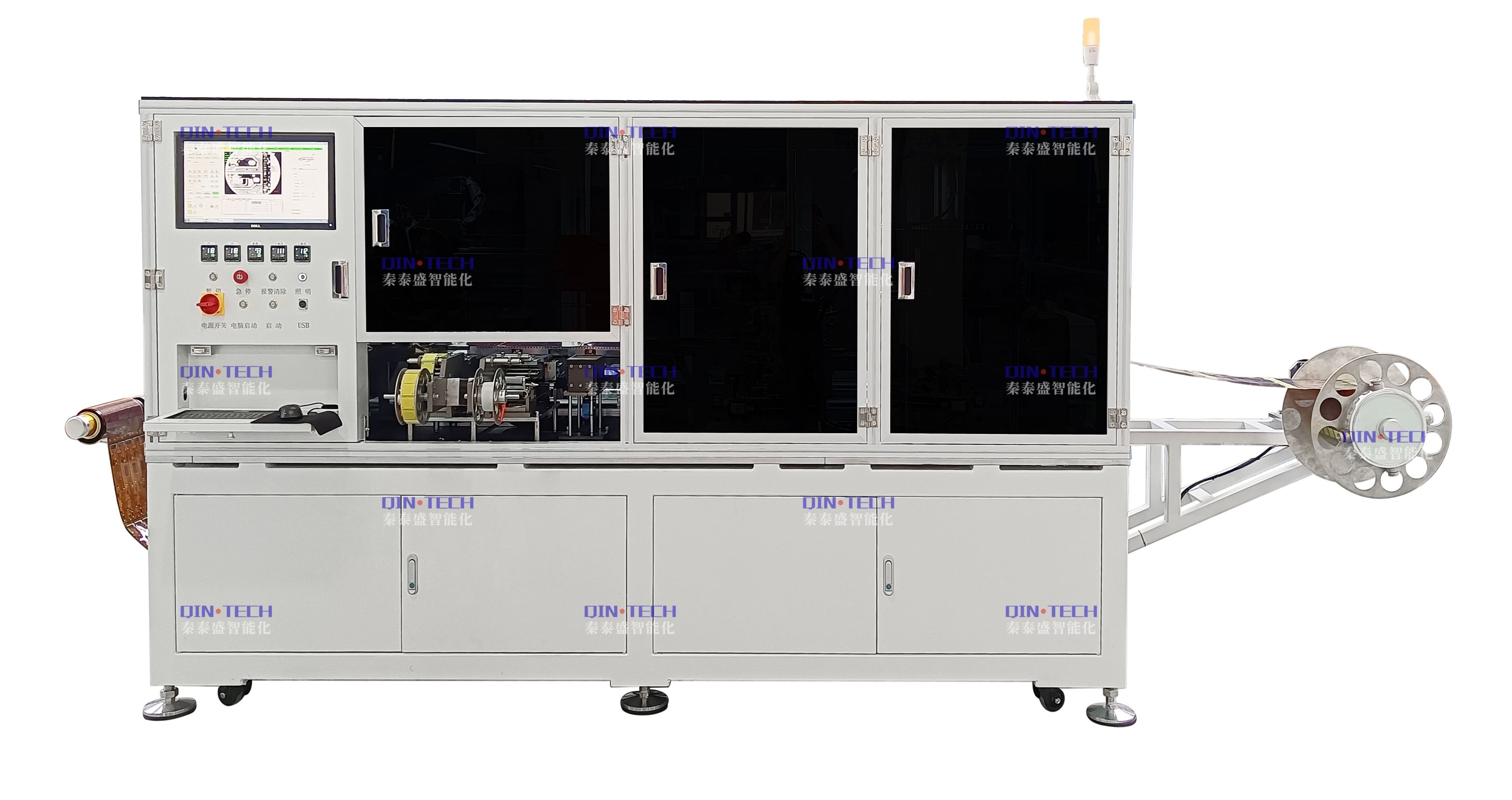

Roll-To-Roll equipment for attaching auxiliary materials and spot heat presses

Category: Technical support

Date: 2024-09-05

Click: 479

Collection:

With the rapid development of technology, automated production has become a core trend in many industries. Against this background, Roll-To-Roll equipment, with its high efficiency and precision, has shown great potential in the field of flexible circuit boards (FPC) and other material processing. Among them, the labeling auxiliary material machine and dot heat press machine, as an important representative of the reel-to-reel equipment, are leading the change in the production mode.

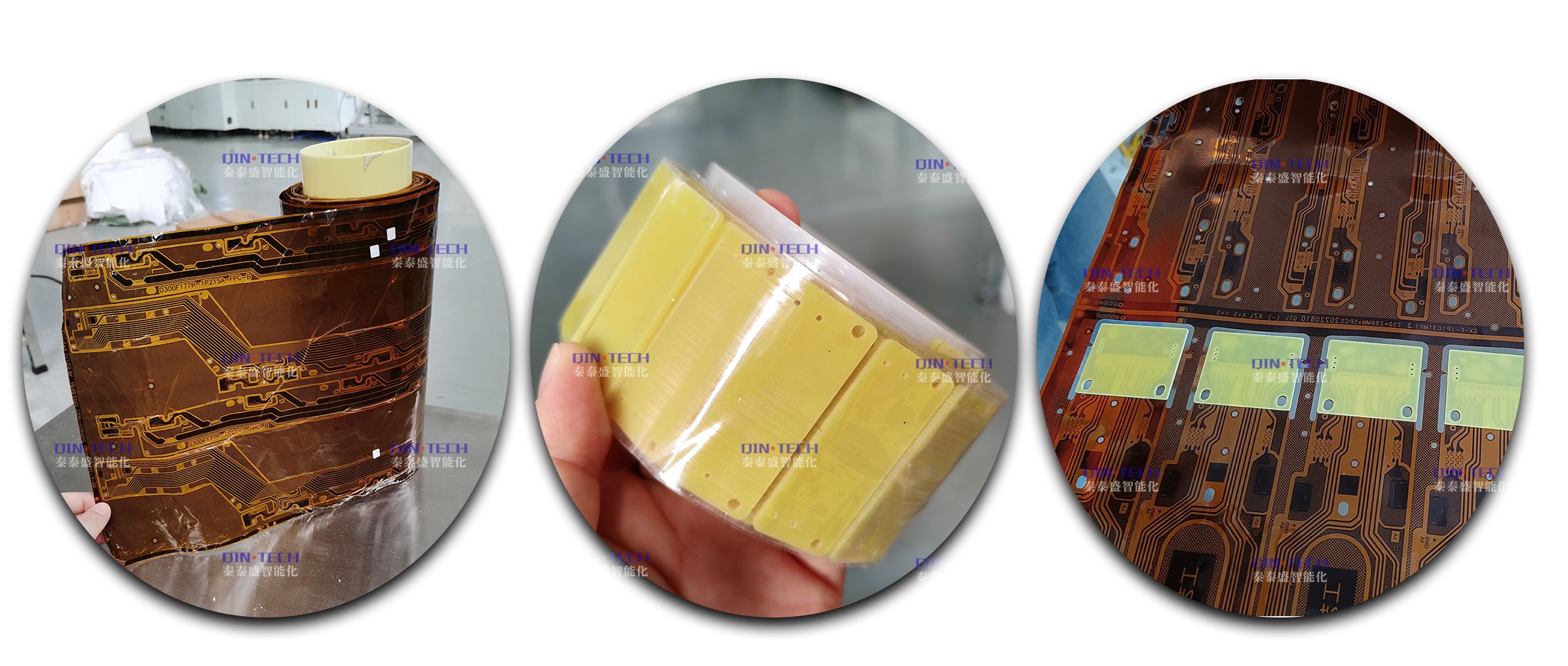

Innovative applications for the labeling of auxiliary materials As a key link in the Roll-To-Roll equipment, the auxiliary material attaching machine is mainly responsible for accurately attaching all kinds of auxiliary materials to the surface of the material, such as reinforcement sheet or foam, double-sided tape, etc. This equipment is especially important in FPC production because it is directly related to the quality and production efficiency of the product. This equipment is particularly important in FPC production because it is directly related to product quality and production efficiency. The modern labeling machine not only realizes fully automated operation but also has a high degree of flexibility and compatibility. First of all, through the precise control system, the labeling auxiliary material machine can automatically complete a series of complex processes such as loading, positioning, mounting, and receiving, without manual intervention, greatly reducing labor costs and labor intensity. At the same time, its mounting accuracy can reach ± 0.02mm, ensuring a perfect fit between the auxiliary materials and materials, and improving the overall quality of the product. Secondly, the labeling auxiliary material machine also has a wide range of compatibility. It can handle materials of different widths and lengths, and adjust the placement position and quantity according to actual needs. This flexibility allows the equipment to adapt to diverse production needs and meet customers' individual customization requirements.

Technological breakthroughs in spot heat presses Point hot press is another important technology in Roll-To-Roll equipment, which is mainly used for hot pressing of materials to achieve the purpose of material bonding and curing. In FPC production, the dot hot press plays a crucial role, which is directly related to the hot pressing effect and the final performance of the product. Modern dot heat press machine adopts advanced heating technology and precise control systems, which can realize precise control of parameters such as hot pressing temperature, pressure, and time. The wide range of pressing temperatures, up to 250°C, can be flexibly adjusted according to the characteristics of different materials, ensuring the stability and reliability of the pressing process. In addition, the hot spot press is highly productive. With a spot heat press time of only 60 seconds, the cycle time is significantly shortened and production efficiency is increased. At the same time, the equipment is compatible with a variety of specifications for the production of products, can be customized according to customer demand for different sizes of products to meet the diverse needs of the market.

The synergy between the labeling auxiliary material machine and the spot heat press machine In the process of FPC production, the adhesion of the auxiliary materials machine and the point hot press often work together to complete the processing of materials. The first auxiliary material paste machine is to complete the accurate placement of auxiliary materials, and then the point of the hot press to paste the material after the hot press processing, to ensure that the auxiliary material and the material are between the strong combination. This synergistic effect not only improves production efficiency and product quality but also reduces production costs and scrap rates. In summary, the paste auxiliary material machine and point hot press as an important representative of the roll-to-roll equipment, in the field of FPC and other materials processing plays an irreplaceable role. With the continuous progress of science and technology and the continuous development of the market, this equipment will be upgraded and improved to provide more efficient, accurate, and reliable solutions for the manufacturing industry. For manufacturers seeking to improve production efficiency, reduce costs, and improve product quality, choosing an advanced labeling auxiliary material machine and dot heat press is undoubtedly a wise choice. |