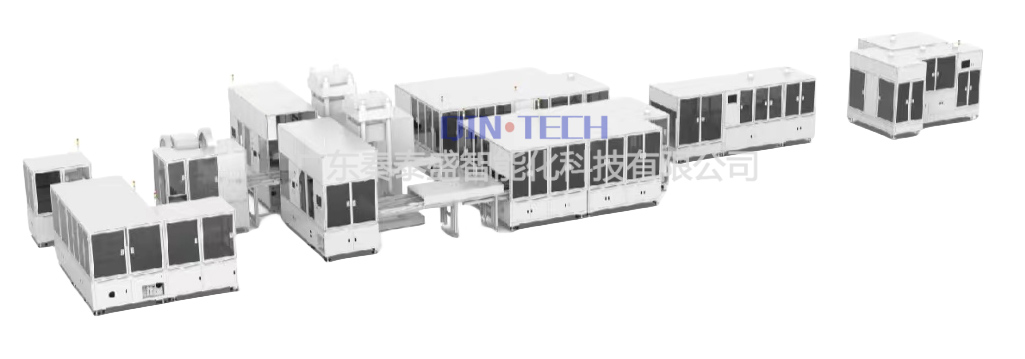

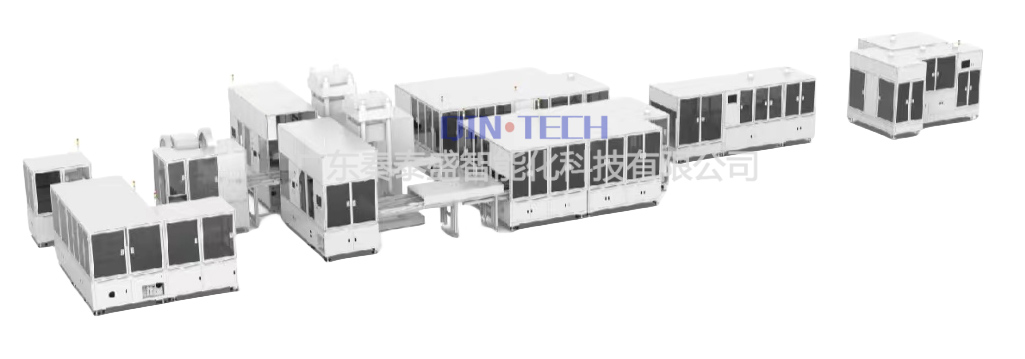

Fully automated production line for aerogel/insulation panel encapsulation in the new energy industry

Qin-Tech new energy industry aerogel/heat insulation board encapsulation automatic production line is our company for the new energy industry research and development of an aerogel/heat insulation board encapsulation automatic production line, this production line not only has the advantages of leading technology and equipment, diversified product composition, high-precision machining quality, flexibility, and intelligence, and so on, and it provides important support for the transformation and upgrading of the enterprise and the research and development of the products.

Compatible finished product size: length 100~250mm, width 100~200mm, thickness 1~7mm;

●Equipment includes: independent automatic gluing and air-drying line, leveling and pressurizing process, automatic assembly, automatic encapsulation, thickness inspection, automatic front and back adhesive backing, automatic point counting, and bundling process, the above equipment is a flexible single unit, can be flexibly connected for common line production or independent operation.

Product composition: Silicone frame, aerogel insulation pad, PET encapsulation film, double-sided adhesive tape; ● Product composition: Silicone frame, aerogel insulation pad, double-sided adhesive tape.

Aerogel insulation mat type: pre-oxygenated fiber mat, glass fiber paper, ceramic fiber paper, organic foam, etc., or aerogel silica, alumina, etc.

●Basic parameters of equipment :

1. Comprehensive capacity of the whole line≧1200PCS/H;

2. Assembly precision: ± 0.2mm, mounting precision: ± 0.2mm

3. Equipment misjudgment rate<4%;

4. Equipment failure rate <4%;

5. Comprehensive product yield of the whole line of equipment≧97%;

6. Equipment operation noise <75Db

7. The energy consumption of the equipment is designed according to the first-class specification;

Advantages: the whole line is intelligent, unmanned, without human involvement (except for line change/feeding)

Fully automatic thickness gauge

●Compatible finished product size: length 100~250mm, width 100~200mm, thickness 1~7mm;

●CT: more than 1000pcs/H

Advantage: Thickness inspection instrument adopts Keens pen type sensor head, with high precision, high feedback, resolution -0.1 μm, accuracy of 1 μm, sturdy and durable.

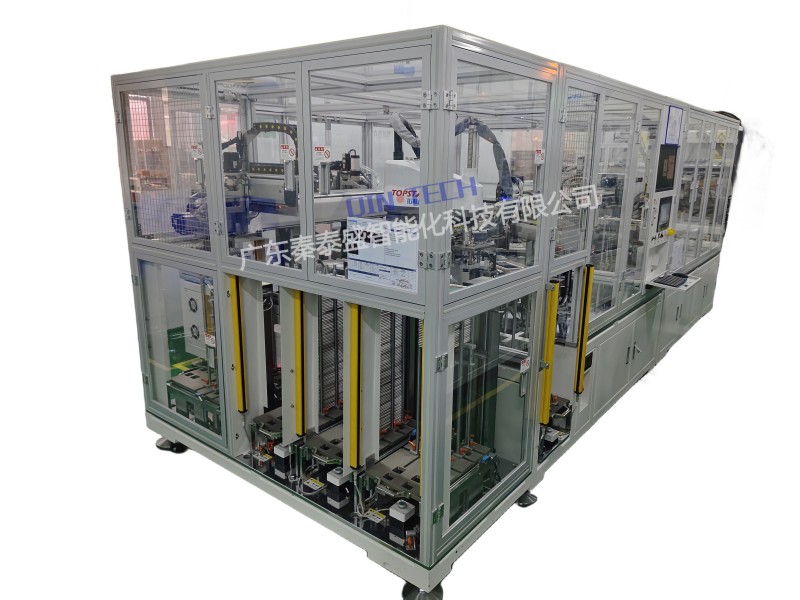

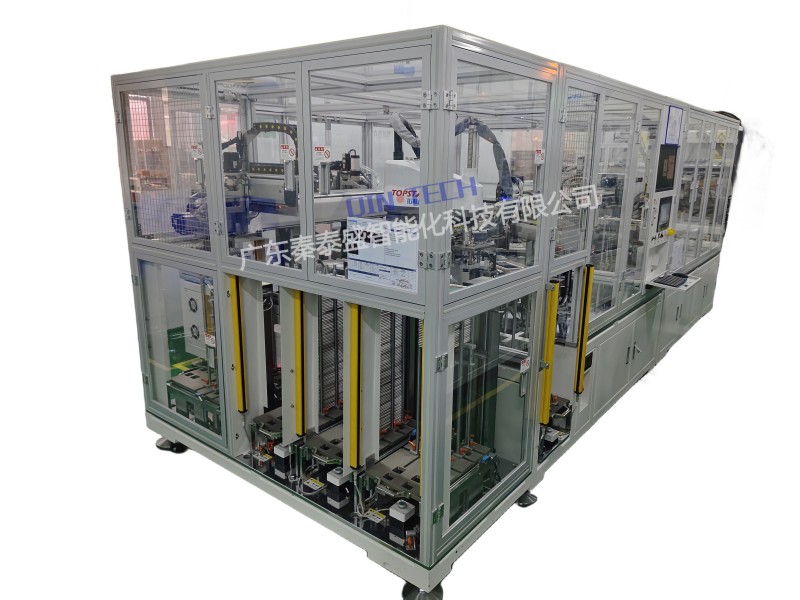

Silicone frame and aerogel automatic assembly machine

●Compatible finished product size: length 100~250mm, width 100~200mm, thickness 1~7mm;

●Assembly precision:±0.2mm

●CT: Double sets≧1000pcs/H

●Equipment misjudgement rate<4%

●Equipment failure rate<4%

●Advantages: Automatic loading and unloading, automatic cleaning and dust removal, stable product quality, unmanned operation.

Aerogel Felt Automatic Leveling and Holding Machine

●Products compatible size: maximum 500 * 600mm (can be customized)

●Maximum pressure nominal: 150T

●Equipment failure rate <4%;

●Advantages: fully automatic loading and unloading, automatic dust extraction, adjustable holding time, adjustable pressure, the holding workstation, and the mobile pressing platform are divided into two channels, alternating operations each time to ensure the efficiency of the equipment.

Fully automatic adhesive backing equipment

●Double-sided brush treatment agent, high-precision pasting front and back, holding pressure, pre-tear film;

●Rolling method to ensure no air bubbles after mounting, mounting precision (±0.2mm);

●CT: greater than 1200pcs/H;

●Products can be compatible with large sizes, can be customized in large sizes on demand;

●Equipment misjudgment rate <4%;

●Equipment failure rate <4%;

Advantages: fully automatic loading and unloading, optional automatic strapping machine to do automatic counting and strapping packaging, brush agent function can be shielded or enabled on demand, brush agent mechanism brush coating evenly, automatic air drying after brushing the agent.