Qin-Tech AZM-ST1 Automatic Aerogel Labeling Machine

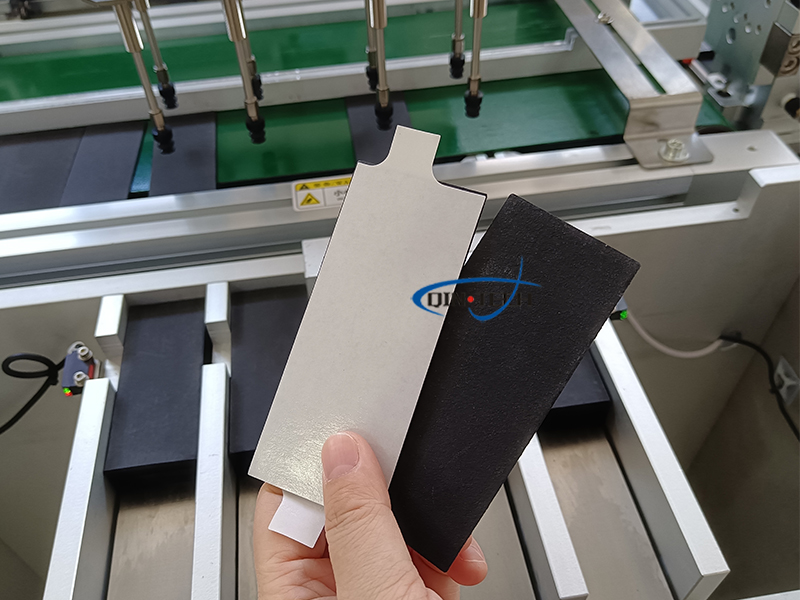

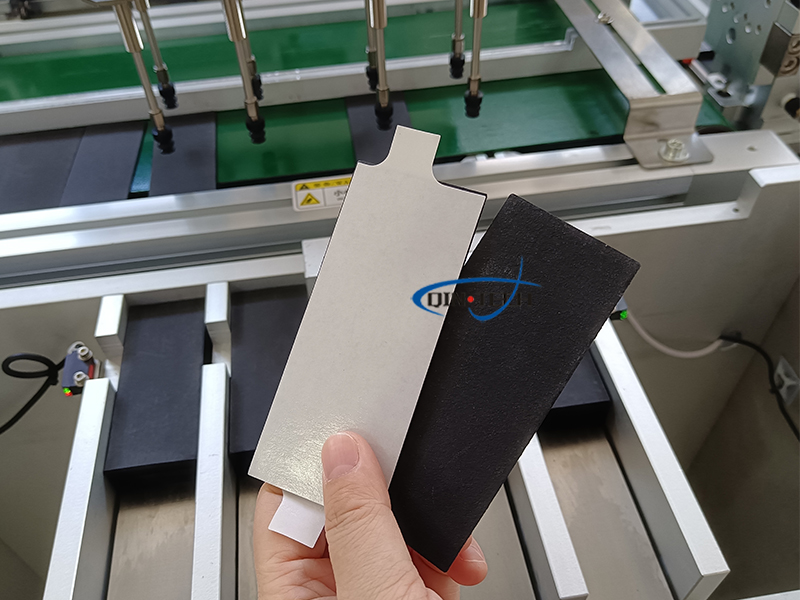

AZM-ST1 aerogel automatic laminating second generation machine is Guangdong Qin-Tech intelligent technology limited company, independent research and development production of a fully automatic paste auxiliary material machine. The equipment can realize the function of automatic product pick-up, automatic glue brushing, high-precision paste front and back side, and automatic material under, the equipment product adopts mechanical positioning angle for positioning, the auxiliary material is CCD visual positioning can ensure the placement accuracy ±0.2mm. the product can be compatible with large size: maximum 220*120mm, minimum 100*45mm.

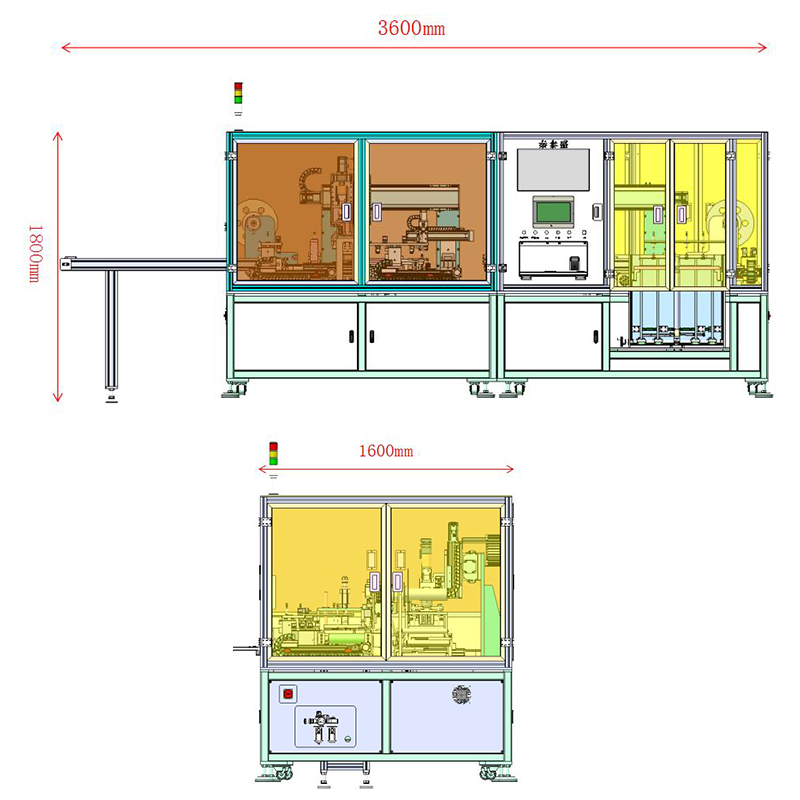

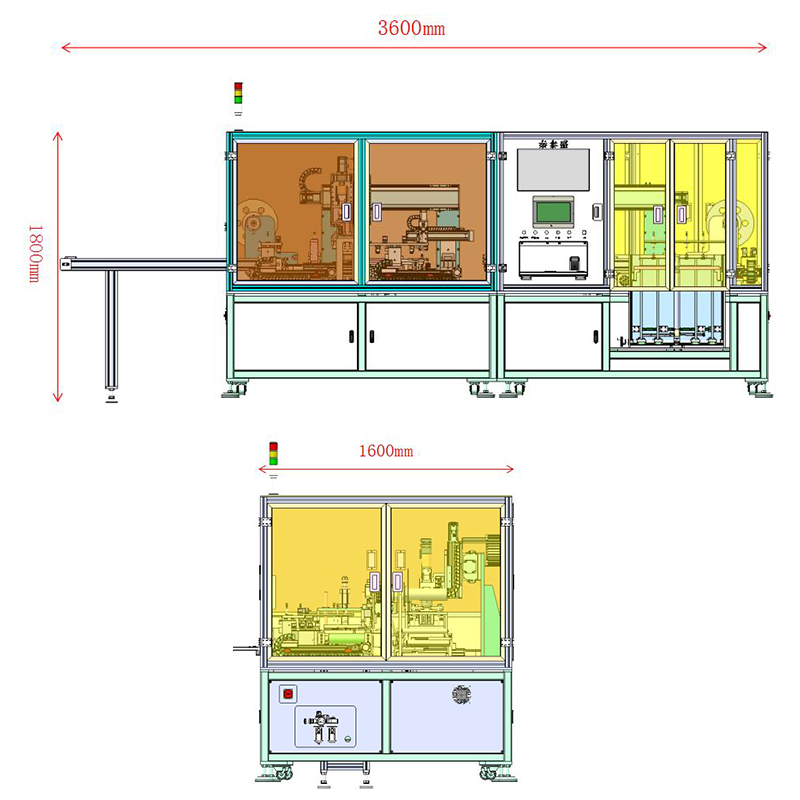

Dimensional drawing of the whole machine:

1. Height of operating table from the ground: 800mm (operating height)

2.Equipment power: ≈ 5.5 Kw

3. Access to power supply: 220V 50HZ

4.Access to gas source: clean gas source 0:4-0.6MPa

Automatic Aerogel Labeling Machine Equipment Introduction:

1. Equipment function: automatic product pick-up, automatic glue brushing, high-precision paste front and back side, automatic dismounting.

2. Functional flow: automatic loading, product glue brushing, front side double-sided adhesive, turning, reverse side glue brushing, reverse side double-sided adhesive, pressing, automatic dismounting.

3. The equipment has four storage bins, each with a capacity of 450mm, which can hold approximately 1200PCS of products at a time according to the thickness of 1.5mm.

4. equipment products using mechanical positioning angle for positioning, auxiliary materials for CCD visual positioning can ensure the placement accuracy ± 0.2mm.

5. Product can be compatible with large size: maximum 220*120mm, minimum 100*45mm.

6. The equipment can choose the brush glue function switch through the software, brush glue mechanism can ensure the brush glue quantity of the product surface evenly, after brush glue will have air blowing mechanism to ensure the glue quantity solidifies quickly.

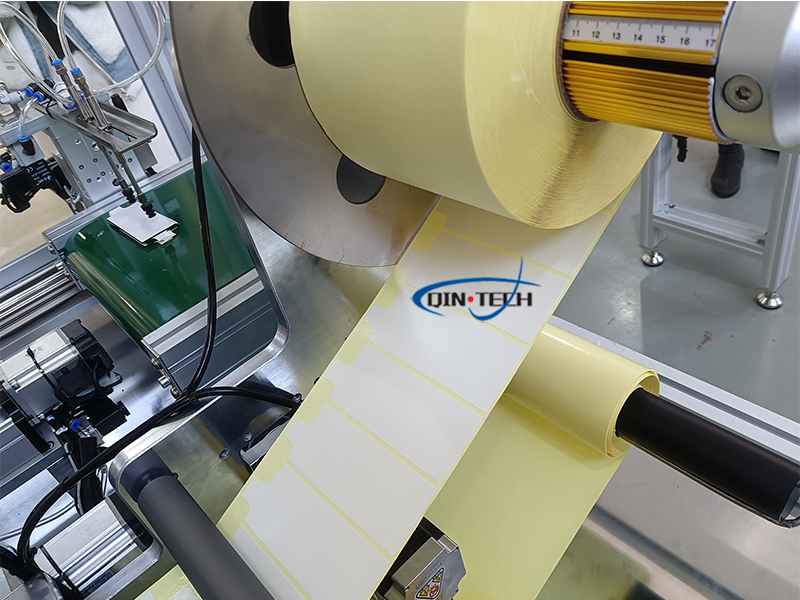

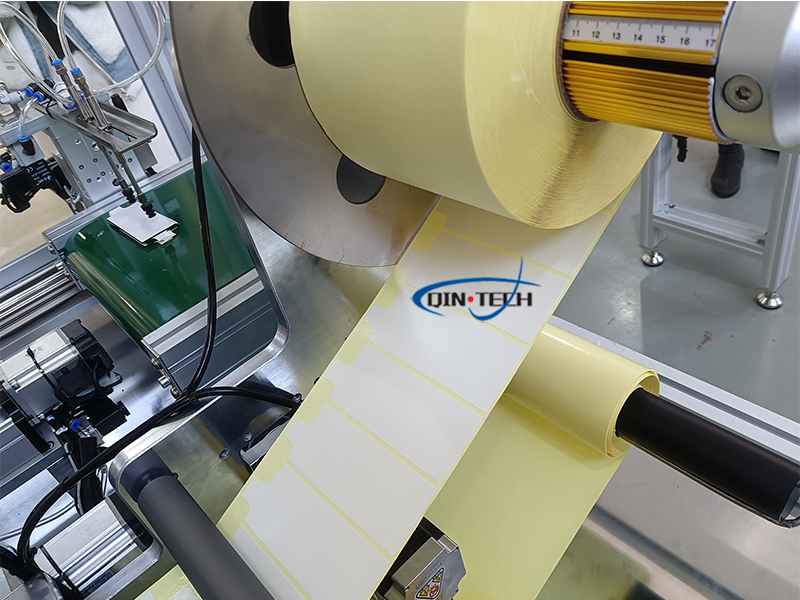

7. The equipment adopts the rolling method when applying the double-sided adhesive, which can ensure that there are no air bubbles between the double-sided adhesive and the product.

Automatic Aerogel Labeling Machine Description of some modules

Description of the loading + front-facing mechanism.

1 Bin loading transfer mechanism to put the shovel piece into the belt line, loading transfer mechanism to take the material on and brush the glue blowing wind

2 Fei Da send glue paper sticker mechanism to take material and stick to the product

3 After pasting the adhesive paper, the adsorption platform retreats to the flip position, the flip mechanism takes the material to flip the conversion surface

The reverse side of the placement and under the material mechanism description.

1 Synchronous shifting mechanism take material to load material, brush glue mechanism brush glue and blowing wind

2 Fei Da sends the glue paper, pastes the glue body to take the glue paper and pastes to the product after the photo

3 Synchronous transfer to take the product with adhesive paper on both sides and put it on the pressing platform

4 Pressing mechanism presses the product together, the finished product is taken by the material feeding mechanism

Automatic Aerogel Labeling Machine Technical specifications

Model

| AZM-ST1 |

|

product size

| MAX:220*120mm MIN:100*45mm |

|

Product thickness range | 1.5-10mm |

|

precision

| ±0.2mm |

|

production efficiency

| ≥600PCS/H |

|

nozzle

| 2PCS

|

|

Feeder

| 2PCS

|

|

CCD

| 2PCS |

|

| MAX:220mm |

|

| MAX:450mm |

|