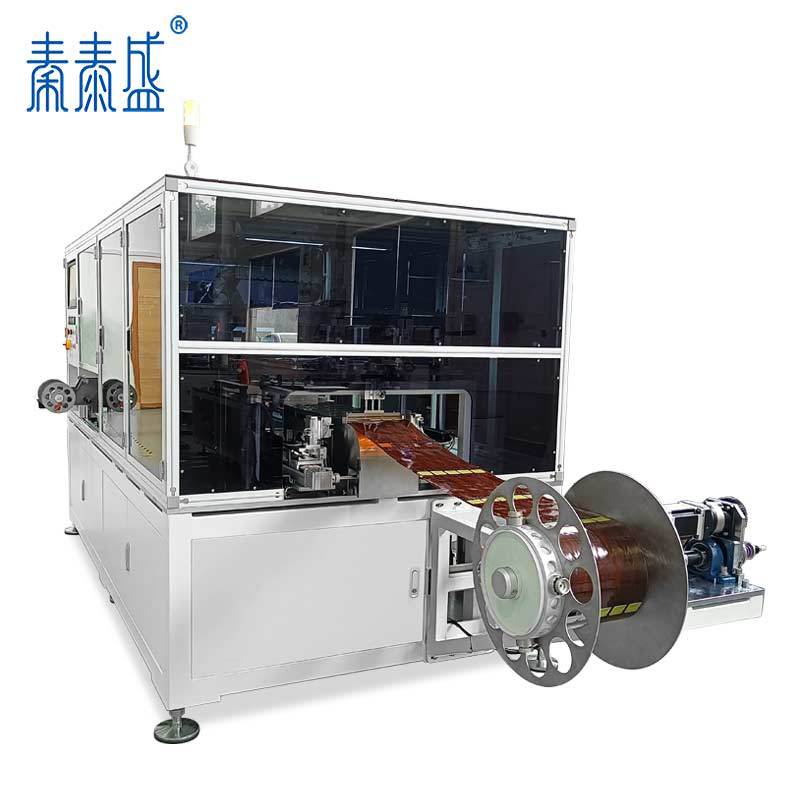

Introduction of Equipment:

1. High speed, high precision and high efficiency

2.FPC coil feeding, reinforcing sheet, finished coil receiving

3. Roll to roll loading and unloading can greatly improve production efficiency, efficient output, labor saving, improve product yield

4. The equipment is equipped with two sets of upper and lower visual system for FPC and insulation sheet compensation, using marble platform + linear motor + grating + high-precision camera alignment to achieve high-precision attachment to ensure high-precision installation

5. Independently developed software system and vision system with reliable performance and high stability, software interface layout cleaning, simple operation and friendly man-machine interaction interface, greatly improving the convenience of manual work

6. The equipment has a pressure retaining mechanism to better stick the reinforcing sheet and FPC, to ensure the reliability of the paste.

Technical Specification:

unit type | ATM-R250 |

|

| ±0.05mm | Remove material deviation |

production takt

| 2.5 S/PCS | Suction cycle time |

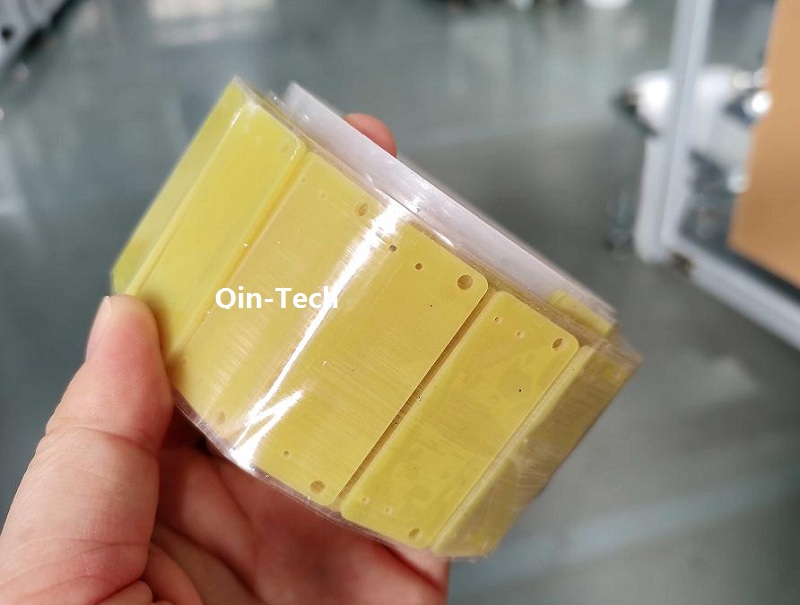

Auxiliary material size | Min:5mm*5mm Max:30mm*50mm |

|

Feeder width | ≤75mm |

|

Feeder Quantity | 2 | roll material

|

No. of nozzles | 2个 | maximum heat-up rate250℃ |

vision | Three sets CCD |

|

FPC width

| Max:250mm |

|

FPC Mounting platform |

|

150℃

|

XY Effective mounting trip | MAX:250*500mm |

|

Strength of reinforcing sheet | With pressure retaining function to ensure that the material will not drop

|

|

Adhesion yield | >99.5% |

|

Production process of products:

1. Unwinding mechanism + conveying active roller will transport the product to the vacuum platform (synchronous winding mechanism) vacuum device suction tight

→ 2.Feida (auxiliary materials) ejection of compact

→ 3. Absorb auxiliary material, CCD accurately identify the auxiliary material contour

→ 4.The rolling material moves from the Y axis to the position of the product to be fitted, the CCD accurately identifies the contour of the product to be fitted, compensates the visual position, and presses down the product to be fitted

→ 5.Secondary pressure retaining mechanism maintains pressure

→ 6.After the Y-axis coiler is pulled to the specified product quantity, the coiler will roll the product (Step 1: synchronous).