◆ Applicable to all circuit boards that need to be labeled or adhesive in the SMT industry, which can improve the SMT online production capacity.

◆ Accurate sticking position, good quality and high stability; avoid manual labeling: low labeling efficiency, sticking offset, blistering and wrinkling, irregular sticking position and a series of problems; effectively reduce product cost and improve product quality Logo aesthetics, enhance product competitiveness.

◆ Can greatly reduce labor costs

◆ Can easily carry out high-speed, high-precision labeling.

◆ The equipment is equipped with anti-fouling facilities on the side, which is more convenient for maintenance, durable and has a long service life.

◆Easy to operate, generally it only takes a week or half to learn

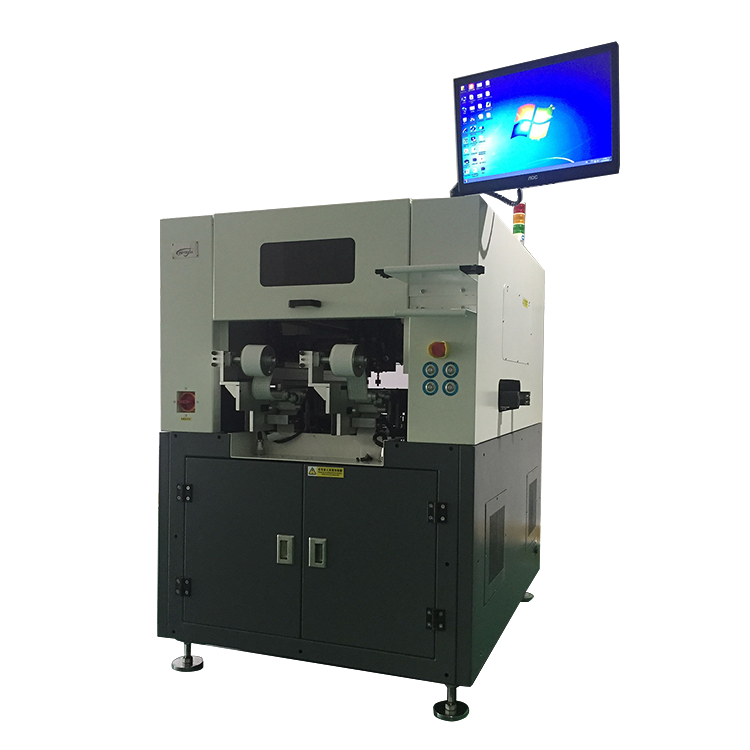

Features:

1. High-efficiency, high-precision label decoration. The full vision positioning and placement system is provided by two high-resolution CCDs and stable vision software, which can correct the errors in the X, Y and R directions of the label and the Fiducial Mark of the circuit board.

Before alignment After alignment

2. More stable and flexible.

High-rigidity base, casting bracket, PANASONICAC servo motor and NSK high-precision screw drive XY axis at high speed, high-precision Z and R axis motors for the placement head can be set up and down 0-35mm ± 0.01mm and angle 0- 360°±0.01° for more flexible labeling.

3. Stable and reliable industrial control system

Based on the Windows operating system platform, it has a multi-level operation interface and a CCD-assisted simplified programming method, providing users with a simple operation interface and easier setting of the machine's operating procedures. It can be attached to veneer and collage and also has SKIP function.

4. The transport track fully conforms to the SMEMA interface. The width can be adjusted automatically according to the set size. The precision stepping motor drives the screw rod. The track can be set with the BYPASS function, and the operation is more flexible. The splint adopts the top design to prevent the circuit board from bending .

5. The electronic label feeder is controlled by optical fiber and motor. The precise feeding method and modular design are easy to operate and easy to replace. Various specifications of label feeders can be made according to customer requirements.

6. Optional automatic barcode recognition system and barcode printer.

Software features:

◎Bad board

◎Support high-precision 2-time alignment

◎Label detection

◎QR code detection

◎Bad label throwing

◎Dead pixel detection

◎The coordinates can be imported from the Excel table

Applicable to various types of labels, anti-counterfeiting labels, SN labels, adhesive tapes, double-sided conductive fabrics with tape, etc.

Software interface

Breakdown of main parts