Equipment composition:

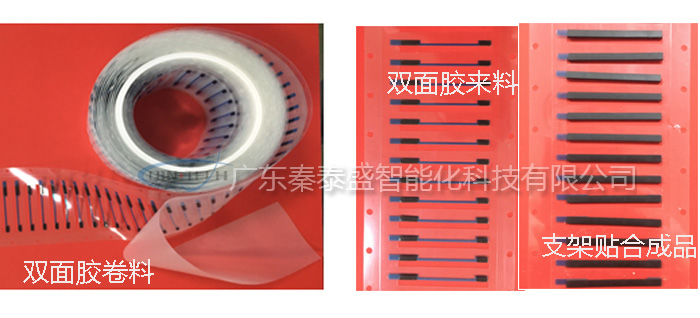

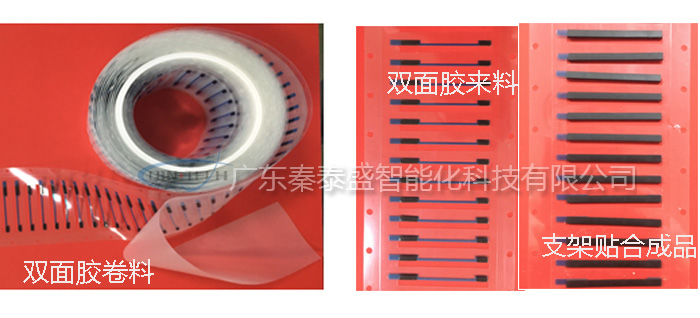

1. Coiled double-sided tape feeding station;

2. Mobile patching platform;

3. Plastic bracket feeding vibrating plate;

4. Plastic bracket suction and mounting module;

5. Two sets of vision systems;

6. Finished product receiving station.

Process Description:

The equipment is fully automatic production.

Manually load the double-sided tape into the equipment, and the equipment automatically feeds; the vibrating plate automatically outputs the plastic bracket; the laminating module automatically absorbs the bracket and performs high-precision (±0.1mm) and high-speed with the cooperation of two sets of vision systems. (1.0-1.3S/PCS) placement; after placement is completed, the receiving mechanism realizes automatic finished product recovery. After a roll is completed, the equipment intelligently reminds the personnel to replace the material.

Equipment hard requirements

1. The automation takes up less space and cooperates with customer standard equipment

2. All kinds of institutions and special planes need to run smoothly, and there should be no phenomena such as not taking materials and leaking materials.

3. The equipment should be safe and reliable, easy to operate, and the noise should meet the national first-class standard.

Process flow description

1. The incoming material of double-sided tape is roll material, which is assembled to the feeding place of the equipment, and the protective film is torn off.

2. The discharge place of the vibrating plate is equipped with electrostatic blowing, and the minimum weight of plastic parts can reach 0.5g.)

3. Mount the X.Y.Z.R axis with a suction cup to remove the plastic parts at the feeding place of the vibrating plate, and then move the bottom camera

4. The head camera takes the position of the double-sided tape,

5. The system will make corrections according to the product and tape position captured by the camera.

6. Precise placement of plastic parts

7. The double-sided adhesive tape is directly stretched to the tape packaging machine,

8. The reclaimer module on the braiding machine takes the product to the rail material of the feeding tray, and loads the product into the braid

9. The receiving tray wraps the products loaded in the tape into coils

| Technical Parameter |

| Overall equipment size (length, width and height) | ≈1500*800*1500 |

| Equipment use voltage (V) | AC 220v 50Hz |

| Air source pressure (Mpa) | >0.6 |

| Mass of the whole machine (kg) | >150 |

| Machine power (kw) | >2 |

| Footprint(mm²) | Same device size |

| Linear motion system positioning accuracy | +/-0.1 |

| Production Efficiency (S/Pcs) | ≈Equal assessment |

| Precision | ±0.1mm |

| MES system function | without |