Model: ATM-460

It is suitable for all kinds of circuit boards in the SMT industry that need to be labeled, adhesive, and self-adhesive;

Establish customer quality traceability system;

Improve efficiency and quality;

Docking SMT production line to realize automation;

Configuration:

Two placement heads;

Up to four feeders can be hung

Equipment advantage

1. Diversity: For different product sizes of customers, a variety of models and sizes of machines are available for customers to choose from, to meet the automatic production of Min: 50*50mm Max: 460*530mm size products.

2. Convenience: Quick-release vacuum nozzle and quick-release feeder structure can quickly replace the nozzle and material according to the shape and size of the product, which greatly saves the time for changing the line;

3. Easy to operate: The simplified and intuitive operation software can quickly set and adjust the machine operation program. The switching time of the old model can be completed within five minutes, and the new model can be completed within 30 minutes. It has veneer and jigsaw attachment and SKIP Function;

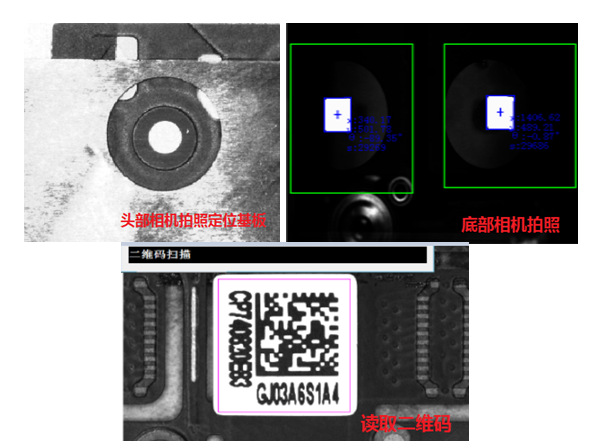

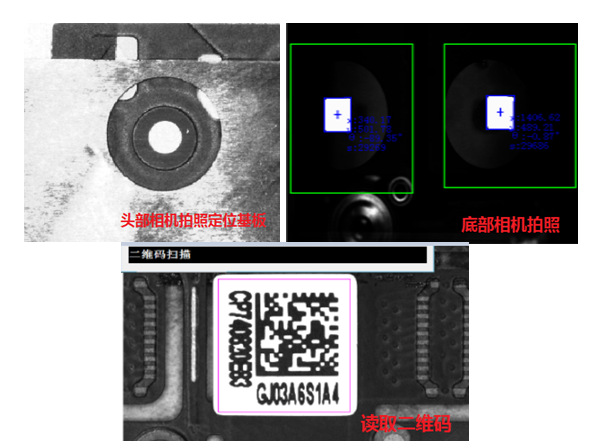

4. The whole system is equipped with high-resolution CCD, high-speed imaging vision system and stable vision module, which can quickly set template recognition for materials of different shapes to ensure the placement accuracy of high-speed production;

5. The whole system adopts imported THK linear guide rails to ensure stable stroke and longevity;

6. The whole system adopts imported Sanyo and Panasonic servos to ensure dynamic stability;

7. Code reading: The vision system supports one-dimensional code and two-dimensional code reading, and is connected with the MES system to realize online production.

Features

★High-efficiency, high-precision labeling

The full vision positioning and placement system is provided by two high-resolution CCDs and stable vision software, which can correct

The error in the X, Y and U directions of the label and the Fiducial Mark of the circuit board.

★High stability and flexible application

High rigidity base, Panasonic servo motor and NSK (or THK, IKO) high precision screw guide drive X-Y axis,

The U-axis can be at any angle of 0-360°, which is more flexible for labeling.

★Stable and reliable industrial control system

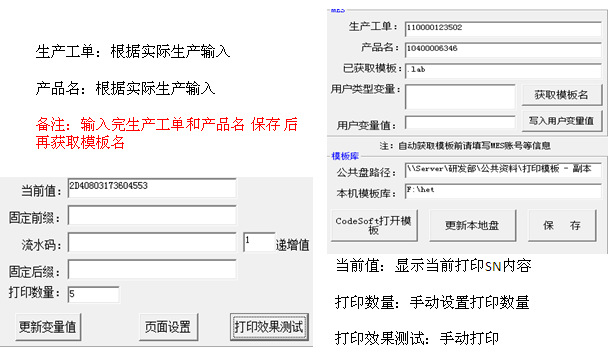

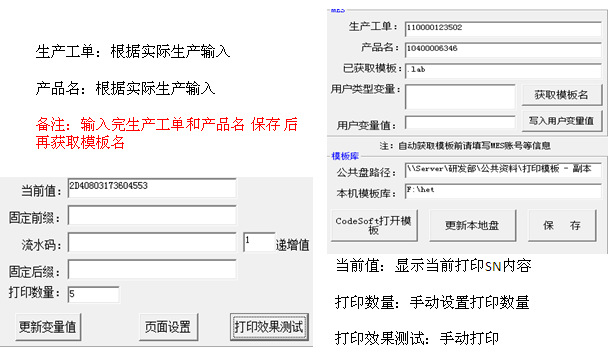

Based on Windows operating system platform, with multi-level operation interface and CCD-assisted simplified programming method,

Provides a user-friendly operation interface and easier setting of the machine's operating procedures. Can be paid for veneer and collage

Has SKIP function.

★Standard SEMA interface transport track, the width can be adjusted automatically

The track can be set with BYPASS function, and the operation is more flexible;

The road board is bent.

★Removable Feeder, standard Feeder installation, easy to replace

The label Feeder is controlled by optical fiber and stepping motor, and the labeling accuracy is high; Feeder

The feeding operation is simple and the replacement is easy. Various label feeders can be made according to customer product specifications.

CCD identification standard mark point positioning;

The head camera precisely positions the product to ensure the accuracy and stability of the fitting coordinates.

The bottom camera performs contour positioning on the fit material to ensure accurate and stable.

After the fitting is completed, you can check whether to read the QR code and upload it to the MES system.

Configurable MES system