Products

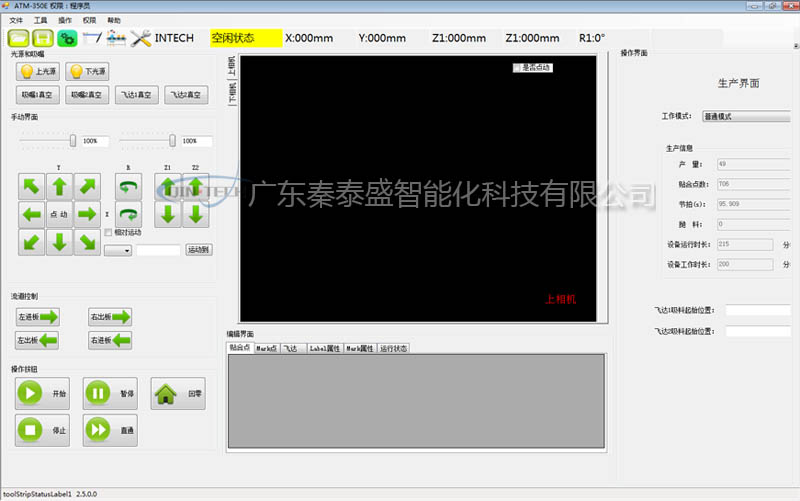

- Automatic labeling machine

- Fully automatic inkjet printer

- Automatic lock screw machine

- Fully automatic lamination machine

- Fully automatic laser marking machine

- High precision large size laminating machine

- Fully automatic visual inspection equipment

- Visual alignment automatic splitting machine

- Non-standard automation equipment