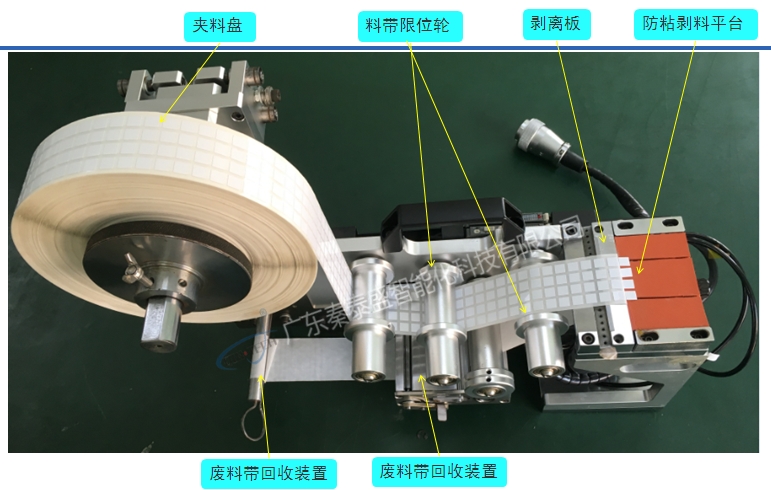

Feeder's functions and applications

Precise feeding of labels of different materials, double-sided tape, double-sided tape conductive cloth, Mylar paper, sealing paper, foam and other materials; can be used for most of the specifications and sizes of materials;

The use of Keyence's high-sensitivity optical fiber and stepping motor can achieve precise discharge;

The special material support platform can adapt to materials of different sizes and different viscosities, and can also accurately discharge some special-shaped materials;

Standard Feida can achieve accurate feeding of 60*50mm size labels at most.

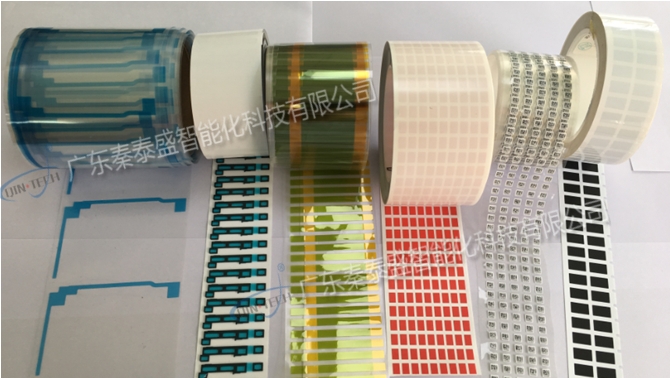

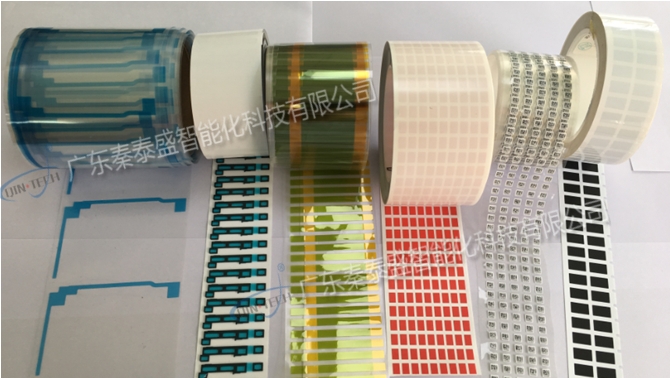

Coil sample

Roll layout requirements

1. The maximum width of the standard Feeder backing paper is 70mm, which needs to be customized;

2. Arrangement of accessories: matrix arrangement, X spacing ≥ 1.2mm (the number is an even number) Y direction spacing ≥ 1.5mm;

3. The safety distance of the edge of the accessories is ≥2mm;

4. The cutting of the accessories should be complete, and the substrate should not be damaged, and the accessories should not overflow;

5. The die-cutting force of the release paper should not be too large. If there are scratches on the release paper, it will be easy to tear when peeled off;

6. The thickness of the release paper is recommended to be ≤0.06mm and the material is soft and easy to peel;

7. If there is a part of the label that is not sticky, the non-sticky part should be peeled off first;

8. The rectangular label should be fed in the direction of the wide side, and the long side should be peeled off;

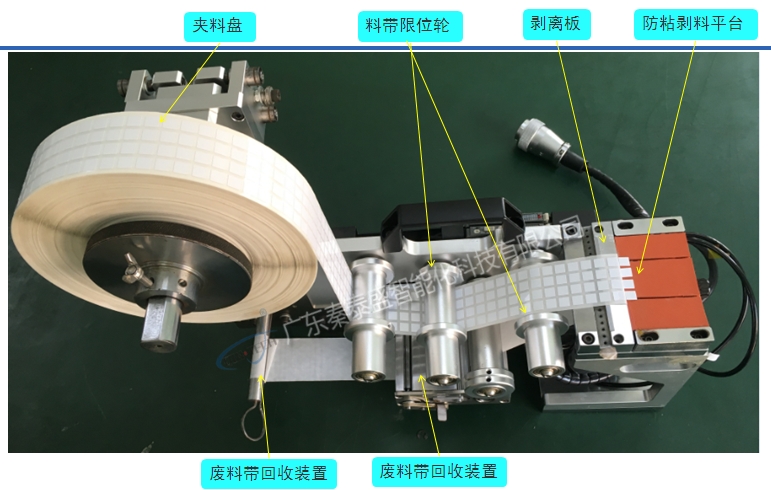

1. Marking speed: 3~5m/min

2. Bidding accuracy: below 0.2mm

3. Label range width: 2mm*2mm-60mm*50mm

4. Minimum gap between labels: 1.2mm

5. Label tube diameter: 76.2±2mm

6. Applicable label bottom paper width: ≤70mm

7. Non-standard customization: the width of the label centrifugal backing paper can be customized, and the applicable width: ≤180mm;

8. Non-standard customization: feeding devices of various sizes and specifications can be customized for the equipment;