Line rigidity requirements

1. Due to the limited space conditions of the production workshop, it is necessary to reduce the space occupied by automation under the premise of satisfying the process production.

2. All kinds of transport aircraft and special aircraft should run smoothly, and there should be no phenomena such as crawling, moving, and deviation.

3. The equipment should be safe and reliable, easy to operate, and the noise should meet the national first-class standard.

●According to the production requirements of the product, quickly realize the function of changing the line, and insert the support structure to realize most of the production

Common process.

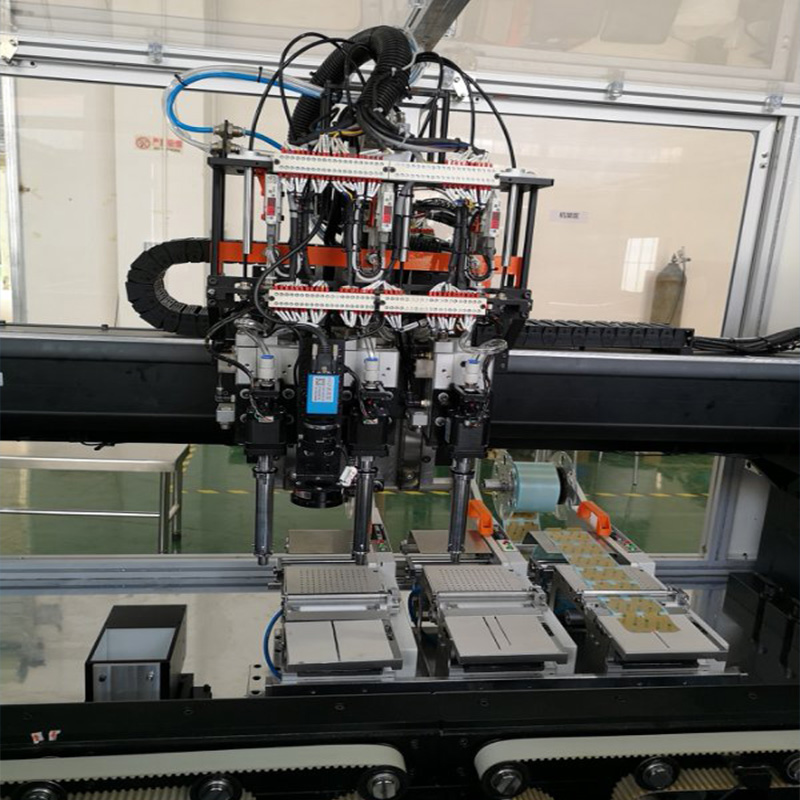

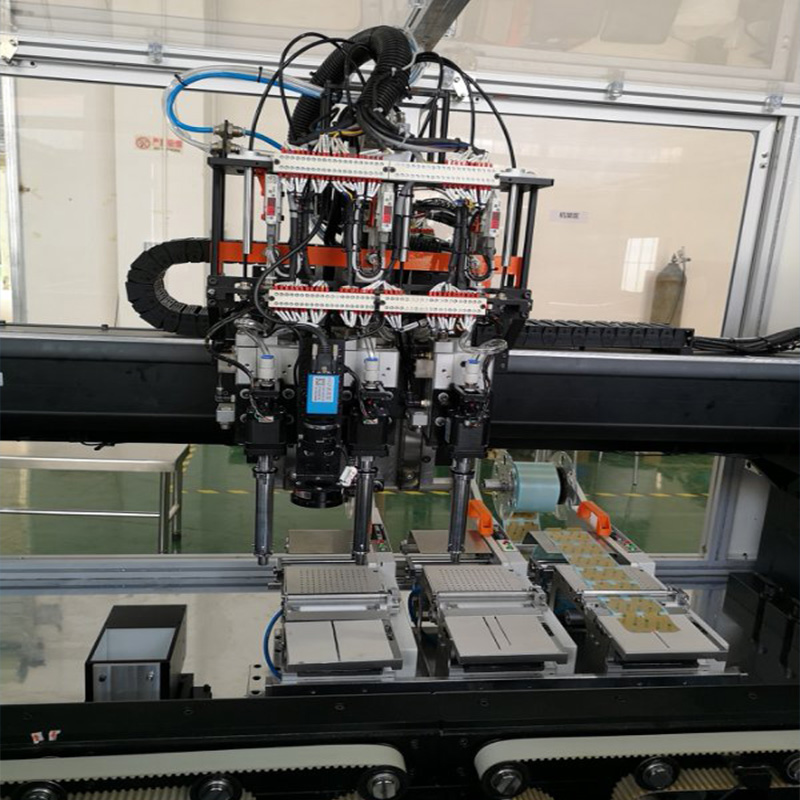

●With two modules on both sides, 10 feeders are used to output (after cutting) 10 kinds of materials of different shapes, and the materials are automatically discharged and double-sided tape/insulation sheets are automatically sucked, and they are aligned and pasted to the corresponding position through the bottom camera.

●The equipment adopts the gantry form of double X-axis and double 4-head suction nozzle mechanism for placement.

A single piece of this product needs to be equipped with two kinds of line card components with different lengths. Therefore, in the case of meeting the efficiency, the single-module double-vibration plate feeding form is used to meet the production needs.

The device reserves expansion interfaces to facilitate product upgrades.

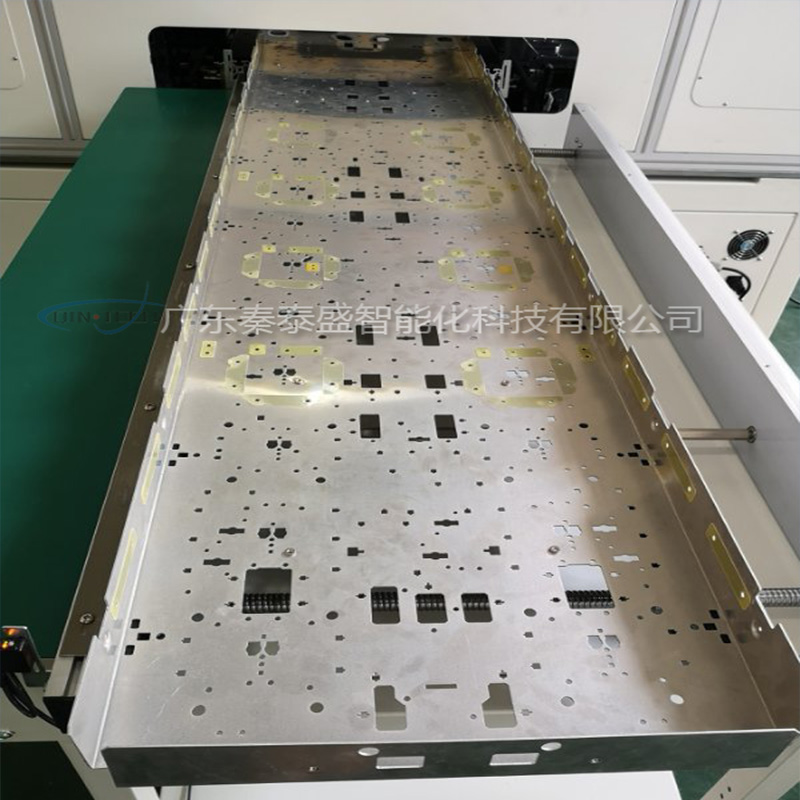

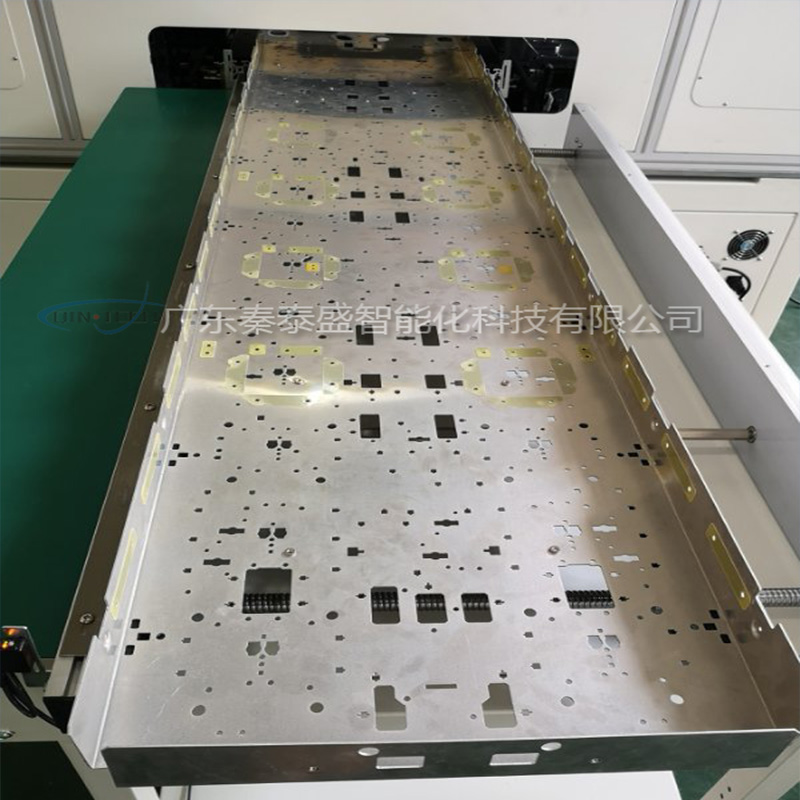

Assembling a product needs to be assembled in three sections. In the initial state, the product enters one third of the equipment. When part of the assembly in this area is completed,

The equipment track is transferred to the second stage of assembly, and so on to complete the assembly of the entire product.

Technical Parameter

General parameters of support column assembly equipment |

Overall equipment size (length, width and height) | 5300*1700*1000 |

Equipment use voltage (V) | AC 220v 50Hz |

Air source pressure (Mpa) | >0.6 |

Quality of the whole machine (kg) | >2200 |

Machine power (kw) | >6.5 |

Footprint(mm²) | Same device size |

Equipment performance parameters |

Linear motion system positioning accuracy (mm) | Screw module+/-0.01 Screw module+/-0.02 |

Production efficiency (min/Pcs) | According to customer requirements |

Orbit streamline speed (mm/s) | 200 |

Visual pixel value (PixelW) | >130 |

Track positioning accuracy (mm) | <+/-0.4 |

Fault warning | Yes |

MES system function | Optional |

The above are some of the parameters, if you need to know more, please consult the online customer service staff. |

The above are some of the parameters, if you need to know more, please consult the online customer service staff.