Equipment introduction

Fully automated valve body assembly line for the water treatment industry

1. It has the ability of fully automatic production of 65HE valve body soft water and water mixing components (mainly for 65 series valves, and further extended to 85 series control valves);

2. The function of quick line change is realized by replacing the product fixture, and the ability of personnel to add materials at 2-hour intervals;

3. All stations are equipped with sensors, CCD or pressure sensors to monitor each assembly station, and the MES system is connected to record production information and abnormal problems;

4. Humanized software and hardware design, front-line workers can take jobs after simple training;

5. Safety protection devices must be installed within the range of motion of all moving bodies. For equipment with a risk of pinching employees, it needs to be designed to be activated by both hands, and the software will alarm in time if there is an abnormality, and make relevant records;

6. The working position of the production equipment for personnel should be safe and reliable, and the working space should ensure that the operator has room for movement.

Dangerous operation points, the design leaves enough space for escape;

7. A protective cover or protective design is installed for each motorized device or components with potential safety hazards.

Features

1. To improve efficiency and save human resources through automated production, all connections and complex movements of the entire line use six-axis and parallel robots instead of manual operations.

2. Use a precision vibrating disc to feed part of the product (in principle, the product will not be damaged).

3. The whole line uses the company's latest version of the upper computer control software to control all actions, so that the whole line operation is smooth and the production efficiency is higher.

4. Use industrial cameras imported from Germany for product outline and position reference matching.

5. Use KEYENCE's latest infrared detection/distance sensor for product positioning to match the vision system more accurately.

6. The whole line adopts the functions of data collection and abnormal monitoring of the production system, so that the production situation is clear at a glance.

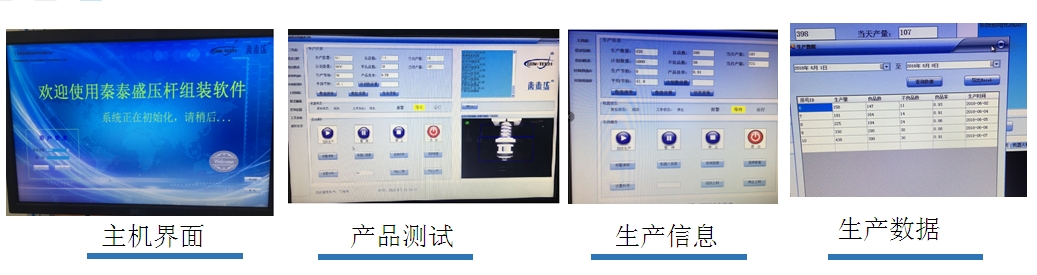

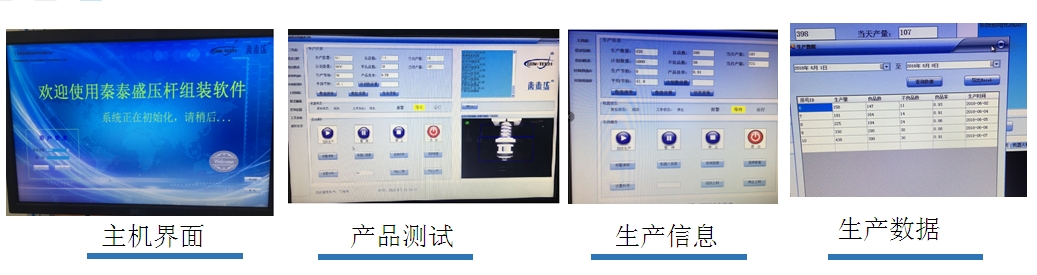

Software description

Self-developed software

The software with independent software copyright monitors the entire production and connects with the customer's MES system in real time to achieve quality control and traceability.

The self-developed software can add new functions in line with the actual needs of the customer's production line, optimize the program more flexibly, and be closer to some operating habits, improving the user's operating experience in the software.

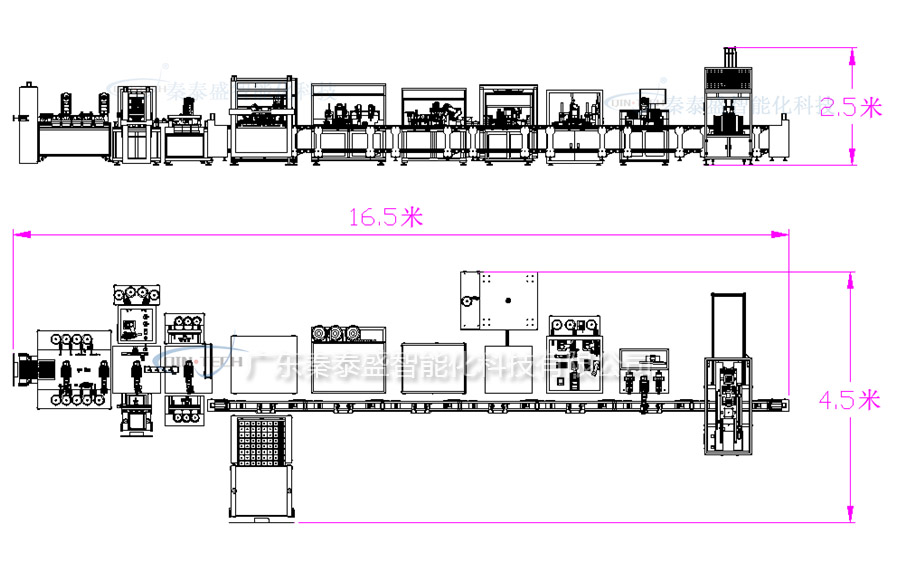

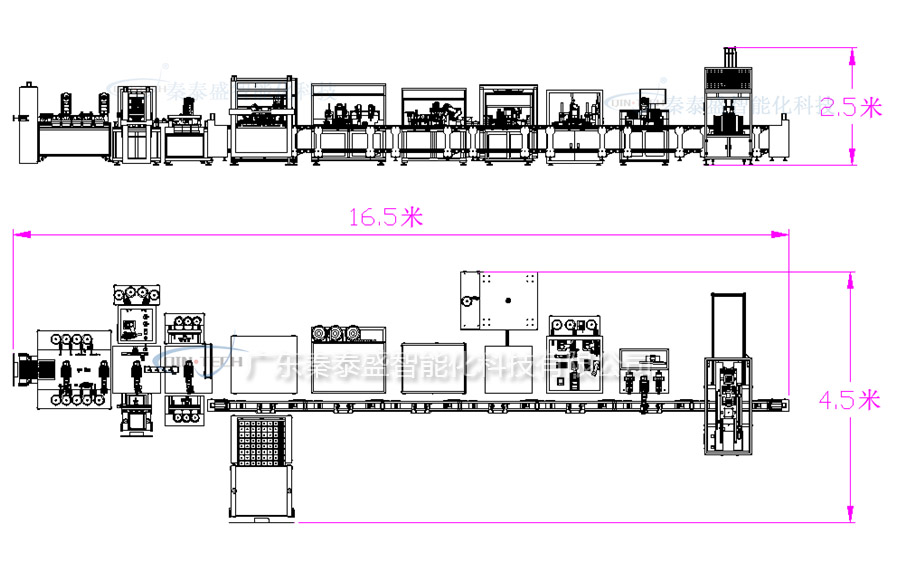

Overall layout of the equipment

Device parameters

|

Project

|

Parameter

|

|

Overall dimension of the whole line mm

|

16.5*4.5*2.5米

|

|

Compatible product series

|

65 valve body & 85 valve body (Compatible with 85HE by adding a water jet part of the machine)

|

|

Compatible product series

|

65 valve body & 85 valve body

|

|

Robot Brand

|

ABB/Kuka

|

|

Number of robots used

|

21 sets

|

|

Product product flow & batch number generation method

|

Based on laser marking

|

|

Product flow & batch number reading method

|

Based on vision processing

|

|

The maximum load of the distal end of the robot

|

8KG

|

|

Theoretical maximum efficiency

|

140pcs/H

|

|

Theoretical maximum service life

|

24H/day

|

|

MES system connection

|

Module docking / whole line docking

|

|

Way to control

|

PC software/motion control card driver

|

|

Stand-alone modular production

|

Can achieve

|

|

Sensor brand

|

KEYENCE/IMMIJING

|

|

Testing base

|

Industrial camera

|

|

Positioning datum

|

High-precision fixture positioning assembly

|

|

Number of cameras

|

>14 sets

|

|

Monitoring method

|

Internal LAN

|

|

Air source requirements

|

≥0.5Mpa

|

|

Voltage

|

220V_50HZ

|