NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

The Green Rebirth of Used Power Batteries: An Innovative Journey of Recycling Equipment

Category: Industry information

Date: 2024-10-30

Click: 1382

Collection:

The Green Rebirth of Used Power Batteries: An Innovative Journey of Recycling and Processing Equipment

Under the blue sky, new energy vehicles are traveling in every corner of the city with their unique charm. They are not only the bright pearls of modern technology, but also an important force in promoting global green transformation.With the retail sales volume of new energy passenger cars exceeding 1.123 million units in September this year, a year-on-year increase of 50.9%, the new energy automobile industry's vitality needs no introduction. 7.132 million retail sales volume in the first three quarters of 2024 signaled that the green revolution is sweeping across the world at an unprecedented speed.However, under this green wave, an urgent challenge is emerging - the recycling and disposal of used power batteries.

Ⅰ. Waste Power Battery: The Hidden Worry Behind the Green Revolution The rapid development of new energy vehicles has undoubtedly made great contributions to environmental protection and energy transformation. However, at the same time, the acceleration of new car launches and the elimination of old cars has led to the generation of a large number of waste power batteries. These batteries are rich in lithium, cobalt, nickel and other valuable resources, if they can not be effectively recycled, not only is a great waste of resources, but also may be improperly handled and cause long-term pollution of the environment. Therefore, the recycling and treatment of used power batteries has become a key link in restricting the sustainable development of new energy automobile industry.

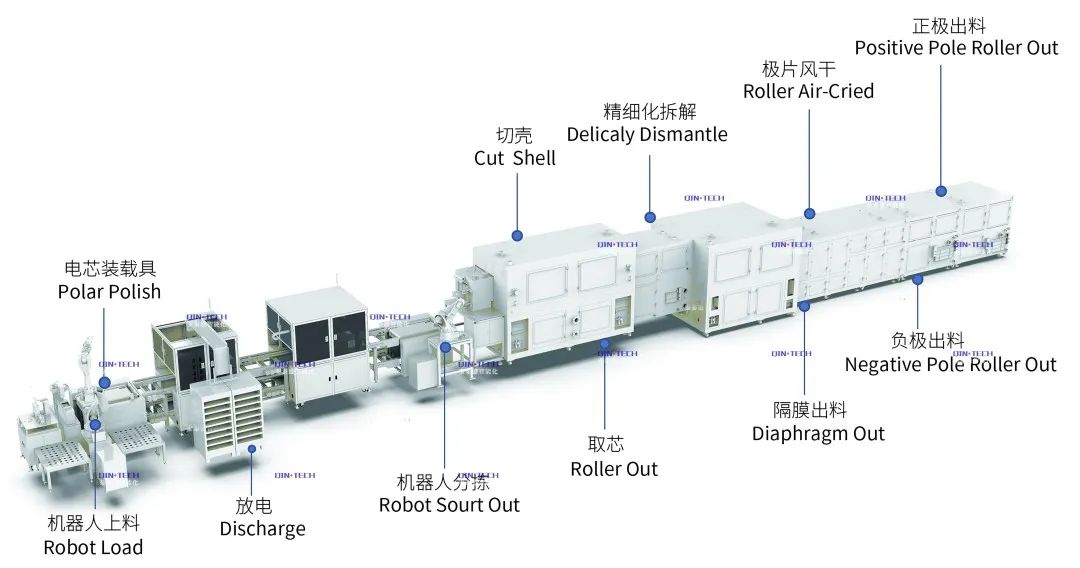

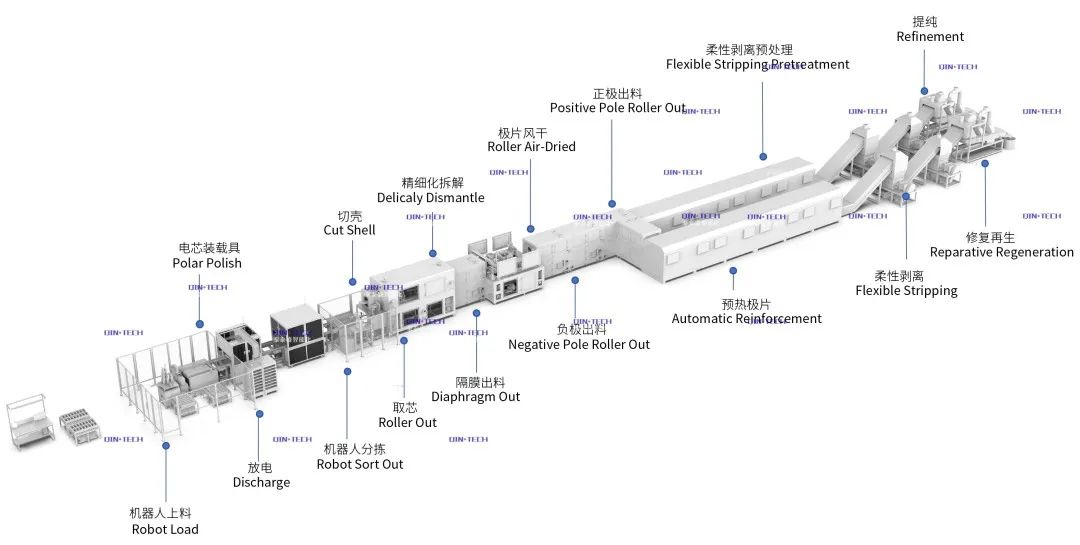

Ⅱ. Innovative equipment: the road to green recycling of used lithium batteries In the face of this challenge, the innovation and development of waste lithium battery recycling and treatment equipment has become the key to crack the problem. In this field, the concept of low-carbon, green, high-value, full-component recycling is widely accepted and put into practice. Among them, Qin-Tech Cycle green recycling production line for waste power batteries has become a leader in the industry with its excellent performance and environmental protection concept.

Five advantages: 1. Subversive: Pure green technology, no pollution, in line with the global dual-carbon goal; 2. Pioneering: the earliest green recycling model implemented in the industry; 3、Intelligence:it has reached a fully intelligent mode without human involvement in the operation; 4、Environmental protection: The whole process adopts pure green technology (including material repair and regeneration & exhaust gas treatment); 5、Innovative:Innovative development of pole piece reuse & waste electricity reuse technology.

1、Intelligent extraction & recycling; 2、Multiple patented intelligent extraction technology can extract the 5 materials in the battery intelligently and accurately, and then obtain the battery-level positive and negative electrode materials through creative repair & regeneration technology; 3, short process, high efficiency; low energy consumption; no pollution; high economic efficiency; 4、The production line can automatically complete the battery conveying, positioning, dismantling and recycling processes, reducing manual intervention and improving dismantling efficiency; 5、Closed operation is adopted in the dismantling process, which reduces the emission of fans and harmful gases, and at the same time, it is able to carry out harmless treatment of waste liquid and waste gas produced by dismantling. The production line adopts advanced physical crushing, sorting and chemical extraction technologies to realize efficient and precise recycling of waste lithium batteries. Through a fine physical crushing process, the batteries are decomposed into different components, and then the valuable materials such as positive electrode materials and negative electrode materials are separated one by one by utilizing highly efficient sorting technology. On this basis, chemical extraction technology further purifies these materials to a standard that can be reused. During the whole process, Qinta Sheng Sai Cola production line strictly follows the principle of low carbon and environmental protection, minimizes energy consumption and waste emission, and truly realizes the green cycle of waste power batteries.

Ⅲ.Technological breakthrough: Promoting the industry to a higher level of development The success of Qin-Tech Sheng Cycle's green recycling production line for used power batteries lies not only in its highly efficient and environmentally friendly recycling and processing capacity, but also in the technological innovation and breakthroughs behind it. The production line integrates a number of cutting-edge technologies, such as intelligent identification and classification technology, high-efficiency crushing and sorting technology, green chemical extraction technology, etc. The integration and application of these technologies not only improves the recycling efficiency, but also reduces the processing cost, providing a brand-new solution for the recycling and treatment of waste power batteries. The recycling and treatment of used power batteries is the key to the sustainable development of the new energy automobile industry. The successful practice of Qin-Tech Cycle's green recycling production line for used power batteries not only shows us the broad prospect of recycling and treatment of used power batteries, but also points out the direction for us to move forward. In this green revolution, everyone is a participant and a beneficiary. Let's work together to promote the recycling and treatment of waste power batteries with practical actions, and jointly guard the green home under the blue sky. |