NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

Lithium battery recycling industry explosive growth, the path of standardization has become a focus

Category: Industry information

Date: 2024-10-21

Click: 1121

Collection:

Lithium battery recycling industry explosive growth, the path of standardization has become a focus First, Background of the rise of lithium recycling industry With the rapid development of the new energy vehicle industry, the decommissioning scale of power batteries is expanding year by year, and the lithium recycling industry is gradually emerging as a new wind industry. According to the Chinese Society of Automotive Engineering data show that in 2023, the total amount of retired power batteries in China has exceeded 580,000 tons, how to effectively deal with and recycle these waste batteries has become a key issue that needs to be resolved.

Second, lithium recycling industry ecological benefits and economic benefits The recycling of used power batteries has significant ecological and economic benefits. On the one hand, through the recycling process, it can promote the recycling of battery metal raw materials, reduce the dependence on the source of mineral resources and environmental pollution, and help realize the goal of carbon peak, carbon neutral. On the other hand, the recycling of waste batteries can also bring significant economic benefits, extracted lithium, cobalt, nickel and other high-value metal materials can be reused in battery production, forming a closed loop of resource recycling.

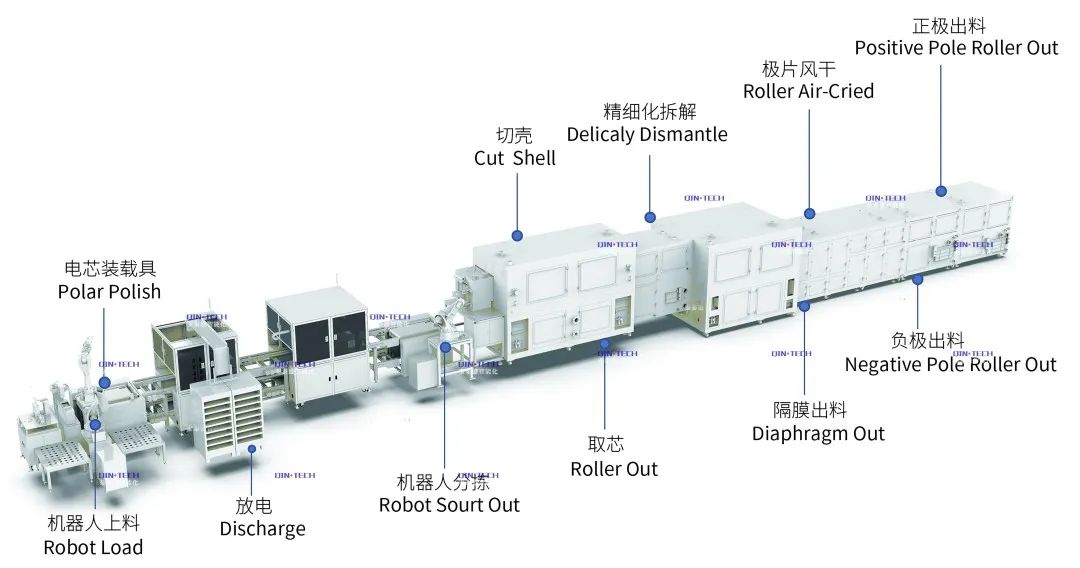

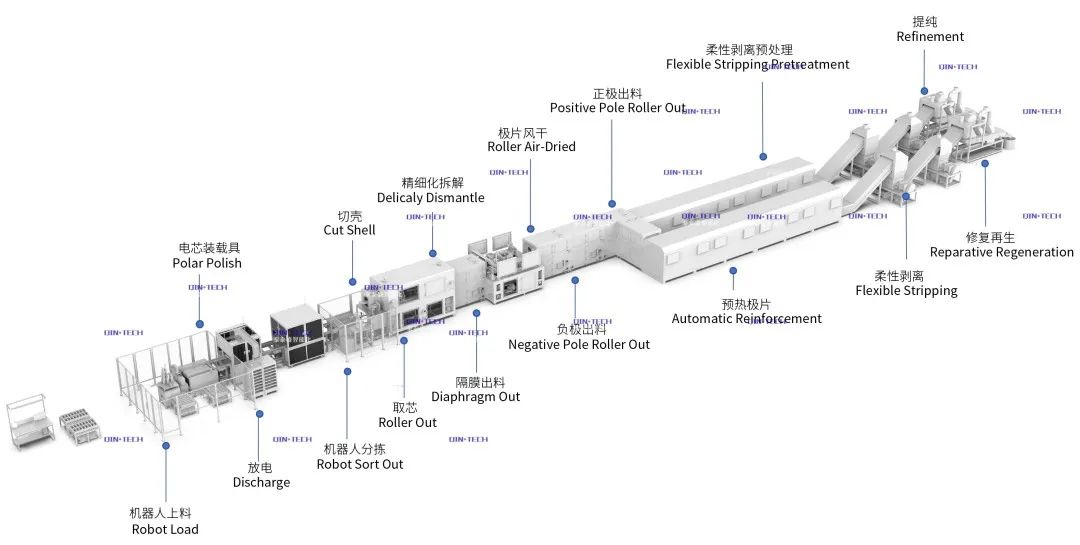

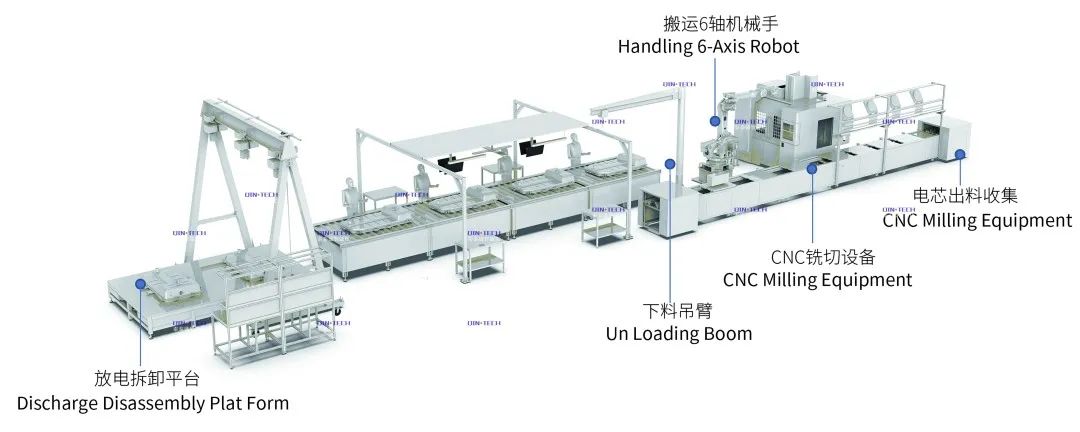

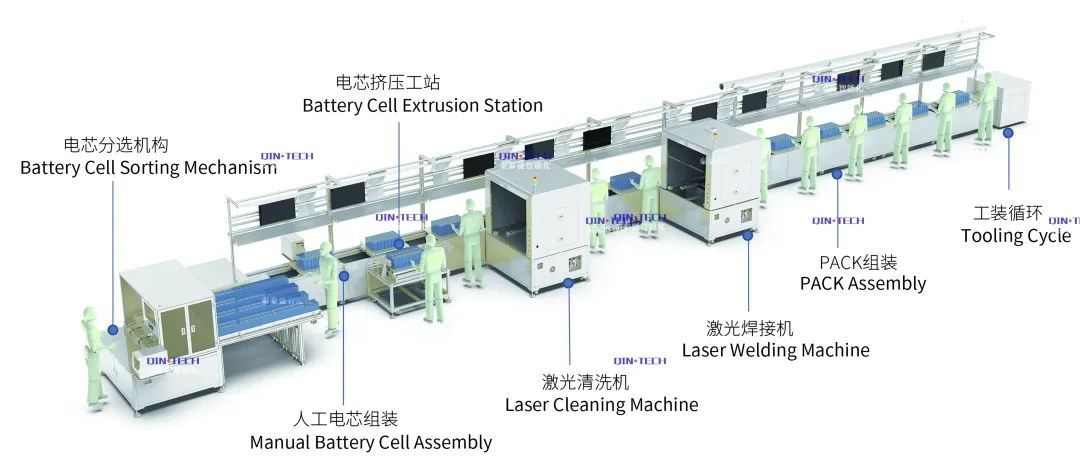

Third, The necessity of standardization of the lithium recycling industry 1. Poor industry standardization: Despite the large number of used batteries, the recycling standardization is poor. According to the Development Research Center of the State Council report, as of 2023, China's new energy vehicle power battery standardized recovery rate of less than 25%. A large number of used batteries are illegally recycled by “workshop-type” small enterprises, and there are serious environmental and safety hazards. 2. Policy promotion and standardization: In order to regulate the lithium recycling industry, relevant departments have issued a series of policy initiatives. For example, the National Development and Reform Commission and other jointly issued a notice to improve the new energy vehicle power battery recycling and utilization of traceability management system; the Ministry of Industry and Information Technology and other five departments jointly issued the “new energy vehicle power battery laddering utilization management approach” to accelerate the power battery recycling system construction. In addition, the Ministry of Industry and Information Technology has also revised and formed the “Industry Specification Conditions for Comprehensive Utilization of Used Power Battery for New Energy Vehicles (2024 Edition)”, which puts forward higher requirements for enterprise site selection, traceability management and energy-saving assessment. 3. Technology and model innovation: In order to promote the standardized development of the lithium recycling industry, a number of innovative technologies and models have emerged in the industry. For example, Guangdong Qin-Tech launched four production lines for this purpose:

Five advantages: 1. Subversive: Pure green technology, no pollution, in line with the global dual-carbon goal; 2. Pioneering: the earliest green recycling model implemented in the industry; 3、Intelligence: no artificial participation in the operation of the fully intelligent mode; 4、Environmental protection: The whole process adopts pure green technology (including material repair and regeneration & exhaust gas treatment); 5、Innovative:Innovative development of pole piece reuse & waste electricity reuse technology.

Process advantages: 1、Intelligent extraction & recycling; 2、Multiple patented intelligent extraction technology can extract the 5 materials in the battery intelligently and accurately, and then obtain the battery-level positive and negative electrode materials through creative repair & regeneration technology; 3, short process, high efficiency; low energy consumption; no pollution; high economic efficiency; 4、The production line can automatically complete the battery conveying, positioning, dismantling and recycling processes, reducing manual intervention and improving dismantling efficiency; 5、Closed operation is adopted in the dismantling process, which reduces the emission of fans and harmful gases, and at the same time, it is able to carry out harmless treatment of waste liquid and waste gas produced by dismantling.

Production line features. 1, dismantling battery pack size compatible range: SUV, small cars, large buses, vans and other types of chassis battery packs and general modules; 2、With servo programmable speed control function to meet the requirements of different material speed beat; 3、Variable frequency conveying speed adjustable, low-speed adjustable stop.

1、The production line can be compatible with assembly/module discharge detection; 2、The production line is highly automated, with less labor involved, which can greatly improve the production capacity of the line; 3、The production line monitors each process in real time, which is convenient to understand the specific status of each process intuitively. Outstanding performance in technological innovation and green development concepts, with independent research and development of a full set of “automation, green pollution-free emissions, low-carbon, environmentally friendly, fine dismantling + gradient utilization” of the entire production process. The application of these technologies and models not only improves the recycling efficiency of waste batteries, but also realizes the efficient extraction and reuse of high-value metal materials such as lithium, cobalt and nickel in batteries.

Forth, Future Prospects With the continuous development of new energy vehicle industry and policy promotion, lithium recycling industry will usher in a broader development space. In order to achieve standardized development, the relevant departments should continue to improve regulations, policies and technical standards system; enterprises should increase technological innovation and investment to enhance the recycling capacity and efficiency; at the same time, all sectors of society should also strengthen cooperation and supervision, and jointly promote the lithium recycling industry. |