NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

Qin-Tech's innovative practice of waste power battery secondary utilization

Category: Industry information

Date: 2024-10-12

Click: 974

Collection:

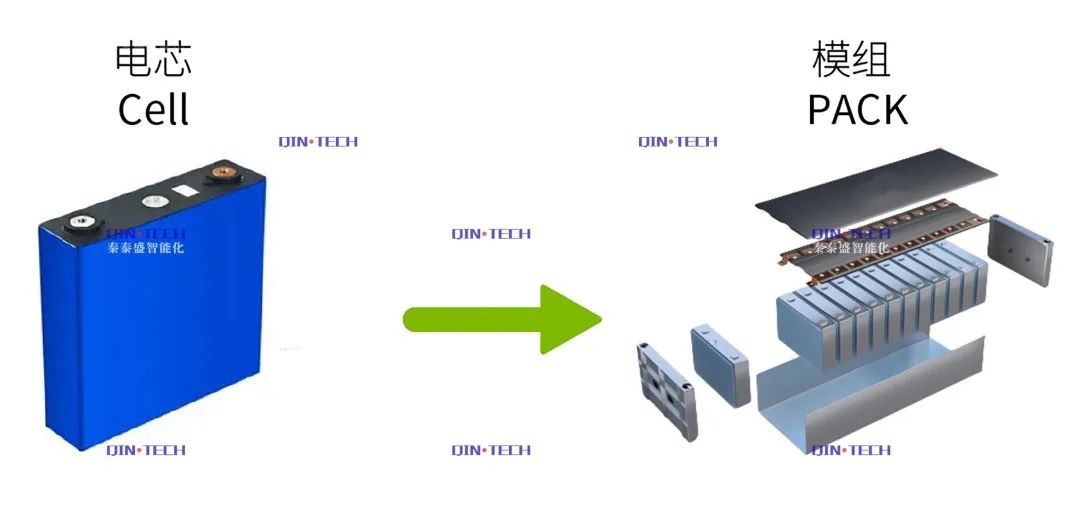

Qin-Tech's innovative practice of waste power battery secondary utilization and battery pack dismantling production line

In the booming development of the new energy automobile industry, the recycling of used power batteries has become a major issue that needs to be solved urgently. With its cutting-edge technical strength and innovative ideas, Qin-Tech has taken a unique development path in the field of secondary utilization of used power batteries and battery pack disassembly, which not only contributes to the environmental protection cause but also injects new vitality into the sustainable development of new energy automobile industry.

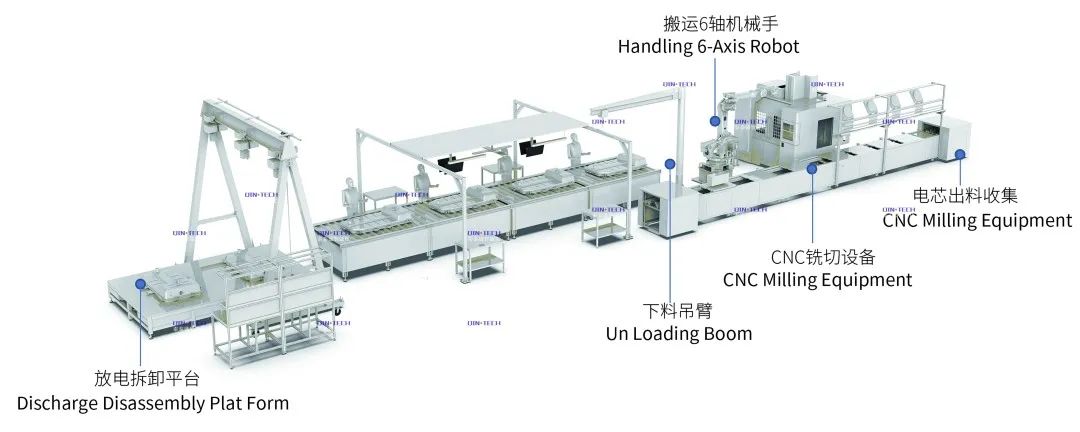

Qin-Tech waste power battery laddering utilization and battery pack dismantling production line is a comprehensive production line integrating intelligence, high efficiency, and environmental protection. The design of the production line takes into full consideration the needs of different sizes and types of battery packs, from SUVs and small cars to large buses, vans, and other types of chassis battery packs, as well as general modules, all of which can find suitable dismantling and reuse solutions on this production line. This wide compatibility not only broadens the application scope of the production line but also greatly improves the recycling rate of used power batteries.

During the dismantling process, Qin-Tech's production line demonstrates its high level of automation and intelligence. From the initial positioning of the battery packs to the fine dismantling, each step cannot be separated from the support of advanced technology. The production line is equipped with a 3D camera data acquisition system, which can accurately capture the three-dimensional data of the used battery packs and provide precise guidance for the subsequent automated dismantling. The multi-machine collaborative operation, whether it is the dismantling of the top cover screws, the handling of the top cover, or the separation of the battery module, all of them realize efficient, precise, and safe operation. This highly automated production method not only reduces manual involvement in the process and lowers labor intensity, but also greatly improves disassembly efficiency and accuracy.

It is especially worth mentioning that the Qin-Tech production line is also characterized by servo servo-programmed speed control function and adjustable frequency conversion conveying speed. The servo program-controlled speed control function enables the production line to flexibly adjust the speed of different materials according to the requirements of the speed beat, to meet the demand for dismantling waste power batteries of various models and states. The adjustable frequency conversion conveying speed further enhances the flexibility and adaptability of the production line, which can realize stable and efficient conveying whether it is dealing with lightweight battery modules or heavy-duty battery packs. What's more considerate is that the conveying speed can even be stopped at low speeds. This design is especially important when dealing with complex dismantling tasks or delicate operations, effectively avoiding problems such as damage to equipment or poor dismantling results due to mismatched speeds.

After dismantling is completed, the Qin-Tech production line is also equipped with an intelligent sorting system, which is capable of categorizing and sorting the different parts dismantled for subsequent recycling and disposal. For key components such as electric cores, the production line also adopts advanced technologies such as laser cleaning and laser welding for processing, ensuring the safety and stability of the connection. At the same time, the production line also focuses on environmental protection and the reuse of resources, minimizing the pollution and waste that may be generated in the dismantling process through refined dismantling and effective recycling.

The successful application of Qin-Tech's waste power battery laddering utilization and battery pack dismantling production line not only solves the problem of difficult disposal of waste power batteries but also prolongs the service life of batteries and reduces the waste of resources using laddering utilization. The utilized battery cells have wide application prospects in the fields of energy storage and backup power supply, which provides strong support for the sustainable development of the new energy industry. In addition, the innovative practice of this production line has also set a benchmark for the industry, promoting the continuous progress and development of waste power battery recycling technology.

Looking ahead, Qin-Tech will continue to adhere to the development concept of green, recycling, and sustainable development, increase R&D investment in the field of recycling of used power batteries, and continuously improve the automation and intelligence level of the production line. At the same time, the company will also actively explore more gradient utilization scenarios, promote the maximization of the value of waste power batteries in more fields, and contribute more power to the sustainable development of the new energy automobile industry. |