NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

Qin-Tech: The Secret of Highly Efficient Operation of CCS Production Line

Category: Industry information

Date: 2024-09-29

Click: 1227

Collection:

Qin-Tech: The Secret of Highly Efficient Operation of CCS Production Line

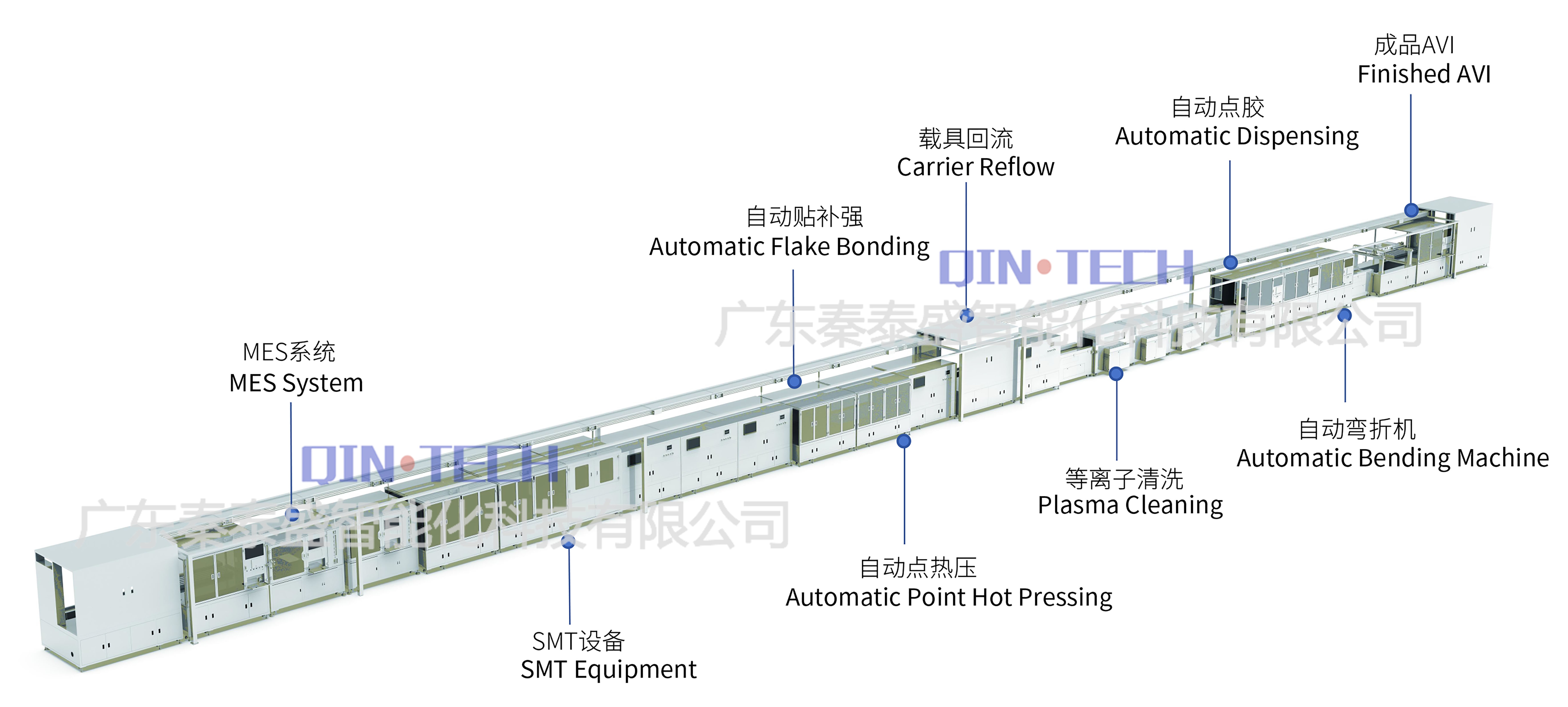

The Qin-Tech CCS assembly line is a production line that integrates a high degree of automation and precision control technology, designed to meet the demands of high-precision assembly and manufacturing. The following is a detailed introduction to the Qin-Tech CCS assembly line:

I. High degree of automation and precise control Automation Functions: The production line realizes the processes of automatic reflux cycle of carrier, automatic centralized board loading, automatic 2D code affixing, automatic hot pressing of patch point, automatic electrical testing, automatic bending, automatic loading of blister tray and automatic distribution of defective products. These automation functions greatly reduce the need for manual intervention, improve production efficiency and reduce production costs. Positioning Accuracy: The visual positioning accuracy of Qin-Tech's CCS assembly line reaches plus or minus 0.01mm, ensuring that the products or components to be processed can be accurately identified and positioned during the production process, and that every step of the operation is precise and error-free. Meanwhile, the operating accuracy of the carrier handling mechanism is +0.05mm, which ensures the stability and accuracy of the products when moving in the production line.

II. process and technological innovation Diversified process: The production line includes MES system, SMT equipment, automatic patch strength, automatic point hot press, carrier reflow, plasma cleaning, automatic dispensing, automatic bending machine, finished product AVI and other links. These links are carefully designed and optimized to ensure the high efficiency and precision of the production process. High efficiency and precision: the maximum size of the auxiliary material can be pasted to 100mm*600mm, the precision of the lamination reaches ±0.15mm, and the hourly output is more than 1500PCS, which means that more high-precision products can be produced in the same time to meet the market's demand for high-quality products.

III. real-time data display and management MES system: The production line has the function of real-time display of MES data, through the addition of video surveillance equipment, synchronized real-time display of equipment related processing data. This enables production managers to grasp the production situation in real time, identify problems and make adjustments in a timely manner, which further improves the production efficiency and management level.

IV. Product quality assurance Automated Inspection: Qin-Tech CCS assembly line is equipped with automated inspection functions, such as automatic electrical testing, which can ensure the stability of product quality. Any product that does not meet the quality standard can be detected and separated in time, thus reducing the risk of non-conforming products flowing into the market. Automatic separation of defective products: The production line also has the function of automatic separation of defective products, which can automatically separate the defective products from the production process and avoid the impact on the subsequent production.

V. Flexibility and Adaptability Flexible Configuration: By flexibly adjusting the configuration of the production line and the process flow, Qi-Tech CCS assembly line can quickly adapt to different production demands and product changes. This flexibility enables the production line to remain competitive in the ever-changing market environment.

In summary, Qin-Tech CCS assembly line has significant advantages and competitiveness in the electronics manufacturing industry with its high degree of automation, precise control, diversified process flow, real-time data display and management functions, and product quality assurance capabilities.

|