NEWSPhone:0769-8166 4889 |

News Details

Position:

Home>

News Details

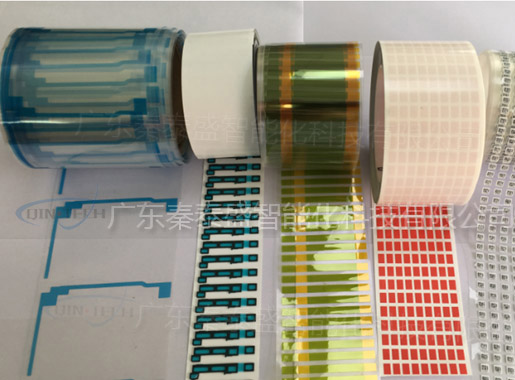

Qin Taisheng launched SMT accessories and self-adhesive automatic placement and foundry services

Category: Company news

Date: 2019-10-16

Click: 1736

Collection:

Are you still troubled by the small quantity of products and the difficulty of manual labor and hesitating whether to use automatic equipment? Are you still considering how long the recycling cycle of the equipment is, and you are late to buy automatic placement equipment? Are you still worried about the quality and delivery due to the low efficiency of manual placement and inaccurate placement?

In order to solve the problems of customers who hesitate to purchase automation equipment due to small quantities, and want to achieve automatic placement to improve placement capacity and placement accuracy, Qin Taisheng has launched various auxiliary materials and adhesives. Automatic placement and processing services, all processes All of them are automated, and the number of workers in a line will be reduced from 16 to 6, which greatly saves labor costs, reduces product production costs and greatly improves product production capacity. Reliable automated products are easier to manage than humans, can effectively improve product quality, and can effectively improve product consistency through the use of automated equipment.

SMT automatic accessories adhesive mounting machine equipment X/Y motor adopts Japanese brand private server motor, high-performance linear module, high-precision CCD and supporting software to fully ensure the accuracy and stability of the machine; high-resolution camera and stable vision software , Stable and efficient positioning algorithm to ensure stable high-speed production accuracy; the equipment uses CCD to identify standard mark points, and locates the head camera to accurately position the product to ensure the accuracy and stability of the fitting coordinates. The bottom camera performs contour positioning on the fit material to ensure accurate and stable. After the fitting is completed, you can check whether to read the QR code and upload it to the MES system. The workshop has a large number of spot prototypes that can be sampled first, and then negotiate cooperation after the sample is OK. Qin Taisheng has always been with professional and dedicated service concept and service spirit, to achieve real production automation, quality automation, benefit automation for customers, reduce labor costs, improve production efficiency, improve product quality, and win the unanimous praise of new and old customers and Long-term support. |