PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

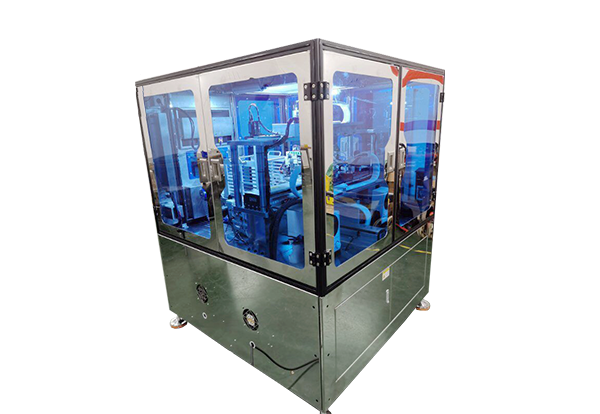

Equipment composition: 1. Automatic feeding mechanism; 2. Carrier pulling mechanism; 3. Double mover linear motor; 4. Two sets of Y-axis modules + precision head + quick release nozzle; 5. Five sets of vision systems (one set of head shooting products, two sets of bottom shooting materials, two sets of feeder shooting materials); 6. Stainless steel mirror shell + FFU, used in class 100 dust-free workshops. Equipment name: Automatic camera module sticking protective cover equipment Model: ATM-260XD2 Equipment introduction: The equipment is suitable for dust-free workshop and fully automatic production Manually put the Trar disc into the feeding rack; the equipment pulling mechanism automatically pulls out the Tray disc camera module; the head CCD identifies and locates the camera module; the suction nozzle takes the lens protection cover from the feeder (two sets of feeder CCDs) Guide the suction nozzle to take more accurate material to ensure stability, two sets of bottom CCD to identify and compensate for the placement accuracy of the protective cover); five sets of vision can ensure the highest ±0.05mm placement accuracy, and the X-axis uses a linear motor to ensure the most 1S/PCS block The placement speed is high; after the placement is completed, the material pulling module automatically puts the carrier back into the material frame until the last plate of material is pasted. After the placement is completed, the entire material frame is manually removed and replaced, which shortens the loading and unloading time and improves the equipment capacity.

下一页

|