NEWS新闻资讯

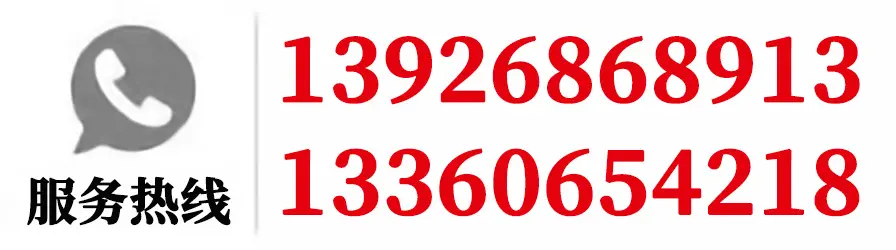

电话:0769-81664889 传真:0769-85356530 邮箱:sales11@in-techgroup.com 地址:东莞市长安镇咸西社区莲湖路6号

|

新闻详情

当前位置:

首页>

新闻详情

Qin-Tech aerogel encapsulation automatic production line's future outlook

专栏:Industry information

发布日期:2024-10-25

阅读量:1392

收藏:

Qin-Tech aerogel encapsulation automatic production line's future outlook: reshaping a new chapter of efficient and intelligent manufacturing In today's fast-changing technology era, high efficiency, intelligence and green have become the key words for the transformation and upgrading of manufacturing industry. With its excellent compatibility and flexibility, Qin-Tech Aerogel Encapsulation Automatic Production Line has not only redefined the production standard of aerogel insulation material, but also led a manufacturing revolution with its intelligent and unmanned operation in the whole line. In this article, we will discuss the unique charm and far-reaching impact of Qin-Tech automatic production line from the dimensions of technological innovation, production efficiency, quality control, environmental protection and energy saving, as well as market application prospects.

I. Technological innovation: flexible monomer, flexible linkage The design essence of Qin-Tech aerogel encapsulation automatic production line lies in its highly modularized flexible monomer structure. This means that whether it is the independent operation of leveling and pressure preservation, automatic assembly, or the automatic encapsulation and thickness inspection, etc., all of them can be flexibly adjusted and combined according to the production demand. This design concept breaks the rigid limitations of the traditional production line and realizes the leap from “customized production” to “flexible manufacturing”. For example, when it is necessary to produce aerogel insulation products of different sizes (length 100-250mm, width 100-200mm, thickness 1-7mm), the production line can be quickly adjusted and configured without large-scale modification, which greatly improves the production flexibility and response speed. II. Production efficiency: high speed and high quality, go hand in hand Efficiency and quality are the two-wheel drive for the survival and development of an enterprise. Qin-Tech automatic production line with its line capacity ≥ 1400PCS / H strong performance, significantly improve the production efficiency. At the same time, the assembly accuracy and placement accuracy are controlled within ±0.2mm, ensuring the high precision and consistency of the products. While pursuing speed, the production line also builds a strict quality control system through the design of low misjudgment rate (<4%), low failure rate (<4%) and high yield rate (≥97%). Behind these figures is Qin-Tech's precise control of every production detail and its relentless pursuit of product quality.

III. Quality control: intelligent detection, accurate and error-free In the tide of intelligent manufacturing, quality control is no longer a simple sampling inspection, but an intelligent monitoring throughout the whole production process. Qin-Tech automatic production line integrates advanced thickness inspection system and intelligent judgment mechanism, which can accurately measure the thickness of aerogel insulation pads in real time, prejudge potential problems through data analysis, and adjust production parameters in time, effectively avoiding the generation of defective products. In addition, the intelligent design of the whole line makes every step of operation in the production process traceable, providing a solid foundation for subsequent quality tracing and continuous improvement. IV. Environmental protection and energy saving: green production, low-carbon future Facing the challenges of global climate change and sustainable development, Qin-Tech automatic production line takes environmental protection and energy saving as an important consideration at the very beginning of its design. The energy consumption of the equipment is designed according to Class I specifications, and the operation noise is lower than 75Db, which not only ensures the comfort of the production environment, but also reduces the energy consumption and carbon emission. Meanwhile, the aerogel insulation mat, as the core material of the product, is widely used in the fields of construction, automobile, aerospace and so on with its excellent thermal insulation performance, which effectively reduces the energy consumption and promotes the green and low-carbon development mode.

V. Market Application Prospect: Wide Coverage, Unlimited Potential With the global emphasis on energy efficiency and environmental protection, the market demand for aerogel insulation materials continues to climb. The launch of Qin-Tech automatic production line not only meets the market's urgent demand for high-quality and high-efficiency aerogel products, but also provides strong supply chain support for downstream industries. From energy saving and heat preservation for smart homes, to thermal management solutions for new energy vehicles, to extreme environment insulation for aerospace, Qin-Tech's products and technologies are gradually penetrating into various industries, showing a broad market application prospect and great potential for development. To summarize, Qin-Tech aerogel encapsulation automatic production line is leading the aerogel insulation material manufacturing industry towards more efficient, smarter and greener with its unique technological innovation, excellent production efficiency, strict quality control, environmentally friendly and energy-saving design concepts as well as a wide range of market application prospects. This is not only the pride of Qin-Tech, but also a shining footnote in the transformation and upgrading of China's manufacturing industry and the journey towards high-quality development. 下一页:找不到相关信息

|