NEWS新闻资讯

电话:0769-81664889 传真:0769-85356530 邮箱:sales11@in-techgroup.com 地址:东莞市长安镇咸西社区莲湖路6号

|

新闻详情

当前位置:

首页>

新闻详情

To solve the industry's "big but not strong" predicament, intelligent manufacturing must start from

专栏:Media focus

发布日期:2018-06-08

阅读量:1672

收藏:

From "going to heaven" to "entering the sea", since the 18th National Congress of the Communist Party of China, driven by major national science and technology projects, my country has conquered a number of key core technologies, developed a number of high-end equipment and strategic products, and cultivated a number of high-tech Enterprises and innovative teams have made remarkable achievements in technology, economy and society. What is a major science and technology project? What are these specials? How much do you know?

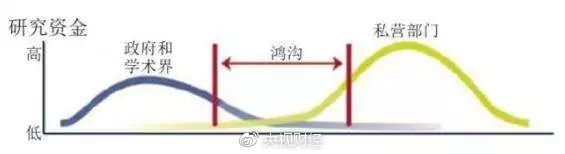

Major science and technology projects are major strategic products, key common technologies and major projects completed within a certain time limit through core technological breakthroughs and resource integration, and are the top priority of my country's technological development. These projects are major projects that can be compared with "two bombs and one satellite" and hybrid rice. The "Planning Outline" announced 13 of the 16 special projects: 1. Core electronic devices, high-end general-purpose chips and basic software 2. Very large-scale integrated circuit manufacturing technology and complete set of processes 3. A new generation of broadband wireless mobile technology 4. High-end CNC machine tools and basic manufacturing technology 5. Development of large oil and gas fields and coalbed methane 6. Large-scale advanced pressurized water reactor and high temperature gas-cooled reactor nuclear power plant 7. Water pollution control and treatment 8. Breeding of new varieties of genetically modified organisms 9. Major new drug creation 10. Prevention and treatment of major infectious diseases such as AIDS and viral hepatitis 11. Large aircraft 12. High-resolution Earth Observation System 13. Manned spaceflight and lunar exploration projects In 2016, a 17th item was added to the National Science and Technology Major Projects we implemented - aero-engine and gas turbine, breaking through the key technologies of "two machines" and promoting the development of large passenger aircraft engines, advanced helicopter engines, heavy-duty gas turbines and other products. As my country enters a critical period of industrial transformation and upgrading, the importance of developing high-end equipment manufacturing industry has become increasingly prominent. Data show that in 2013, the output value of my country's equipment manufacturing industry exceeded 20 trillion yuan, accounting for more than 1/3 of the global equipment manufacturing industry. However, the industry is large but not strong, and the independent innovation capability is weak. There is still a big gap in industrial development compared with developed countries in Europe and the United States. According to the three-step strategy for the upgrading of equipment manufacturing industry formulated by my country, the goal is that when the founding of the People's Republic of China is 100 years old, China will become a manufacturing power that leads the development of the world's manufacturing industry. my country will enter the second phalanx of the world's equipment manufacturing powerhouse, and some high-end equipment manufacturing industries will be the first to enter the international advanced ranks. How to break through the predicament of my country's industry being "big but not strong"? In the process of scientific and technological research, what is the key to achieving results? Li Yizhong, former minister of the Ministry of Industry and Information Technology, walked into the "China Economic Lecture Hall" and explained it for us. Li Yizhong emphasized that to build a manufacturing power, its main line is the deep integration of "two modernizations": industrialization and informatization. Its main attack direction is intelligent manufacturing, and its action path is Internet+. He described the path to improve intelligent manufacturing from three aspects. 1. Carry out scientific and technological research around intelligent manufacturing Li Yizhong said in his speech at the "China Economic Lecture Hall" that while tackling key scientific and technological problems, we must vigorously strengthen the transformation of scientific and technological achievements, and the key is the issue of funding. "During research and development, funds are still guaranteed. Once the project is established, whether it is national investment, private investment, or bank loans, it is also guaranteed. The problem is that the transformation of scientific and technological achievements in the middle, the industry has given it a terrible fear. It's called 'Death Valley'."

(As can be seen from the figure, in the process of transformation of scientific research results, the role of researchers increases from strong to weak, and the role of enterprises from weak to strong. There is a weak area in the middle, which is the so-called "Valley of Death".) The scientific and technological personnel in colleges and universities are good at the front-end work of the industrialization process of achievements, and the follow-up work of product development and industrial production is also very heavy. In addition, enterprises have the instinct to pursue profit maximization and are unwilling to take many risks in the application of scientific and technological achievements. Therefore, it has become a The "Valley of Death" of scientific research results. Li Yizhong said: "You have achieved results, but you have not transformed. How should the "valley of death" in the middle be transformed? This requires our finance, technology finance, and various funds to invest in this transformation." 2. The combination of production, education and research Li Yizhong said in his speech at the "China Economic Lecture Hall" that it is very important to tackle key technical problems common to the industry. "The common technology of the industry and the special equipment of the industry need to be researched and developed, and there are differences between industries. For example, for electric vehicles, the key is the battery, which is the key technology."

In his speech, Li Yizhong gave an example: "We have been fighting each other for a long time. You also engage in R&D, I also engage in R&D, and he also engages in R&D, but the results are all low-level. There is a term called the energy density of batteries. We have been at 150 (Wh/kg) for a long time, which is a low level, and we can’t get up to it, because we are fighting each other. After that, we tackled the common technical problems of the industry, and let the Nonferrous Metals Research Institute take the lead, and some well-known enterprises participated. As a result we are on the road very quickly. Now planning to 2020, this energy density has doubled from 150 (Wh/kg) to 300 (Wh/kg), which will definitely be achieved earlier. This can catch up The level of the United States, the level of Tesla.” During the speech of "China Economic Lecture Hall", Li Yizhong emphasized that intelligent manufacturing should start with building production lines, digital workshops and intelligent factories, which can be divided into five entry points. 1. Digital R&D and design To engage in R&D and design, use digital tools, three-dimensional fine description, simulation, high-speed computing, and improve efficiency. 2. Electronic information technology The integration is applied to the product to improve the function, quality and added value of the product. The most prominent among them are the key components, components and key materials. 3. CNC manufacturing equipment Equipment should be CNC-based, such as high-end CNC machine tools and industrial robots. In 2015, my country's numerical control rate was 27%, and in 2016, it was 46.4%. In recent years, it has been relatively fast. Only in this way can precise manufacturing be achieved. 4. Upgrade from automation to intelligence Let the machine learn, let the machine have wisdom, and let the machine generate instructions by itself. 5. Specify the intelligent manufacturing process Compile a process, standard, process index, and standardize the manufacturing process to adapt to intelligent manufacturing. Enterprise's own efforts In his speech in the "China Economic Lecture Hall", Li Yizhong believed that from the perspective of the industrial Internet, technological breakthroughs should start from enterprises. "The enterprise has an intranet and an extranet. The intranet is to connect the independent physical units in the enterprise, such as machine tools and equipment, to become the Internet of Things. Not only that, but also to connect communications with sensors and command systems to make it Wisdom." The Internet of Things is an important part of the new generation of information technology, and it is also an important development stage in the information age. As the name suggests, the Internet of Things is the Internet of things connected. This has two meanings: First, the core and foundation of the Internet of Things is still the Internet, which is an extended and expanded network based on the Internet; Exchange and communication, that is, things go hand in hand.

It is not enough for an enterprise to have an intranet alone, and an extranet, which is the supply network. Li Yizhong emphasized: "Suppliers supply raw materials, energy, your sales network, your customers, your shareholders, your stakeholders, your partners, and everyone should be interconnected. We have the successful experience of the enterprise, It is necessary to develop the leading role of leading enterprises, cultivate industry networks and regional networks, and when industries and regions are done well, our national industrial Internet will be a matter of course.” This article is excerpted from: CCTV Finance

下一页:找不到相关信息

|