PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

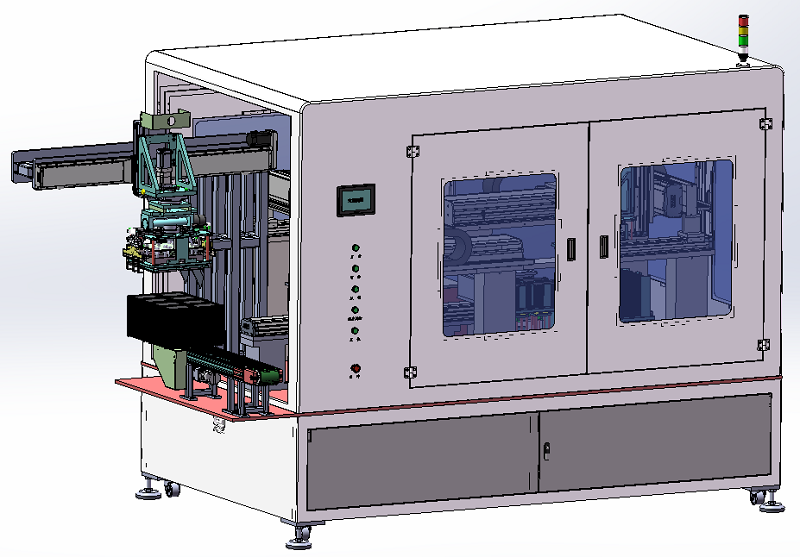

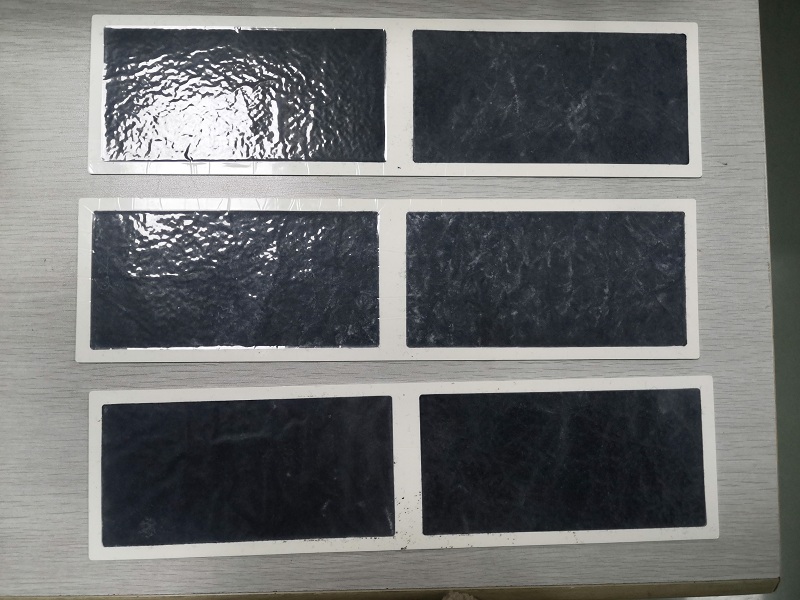

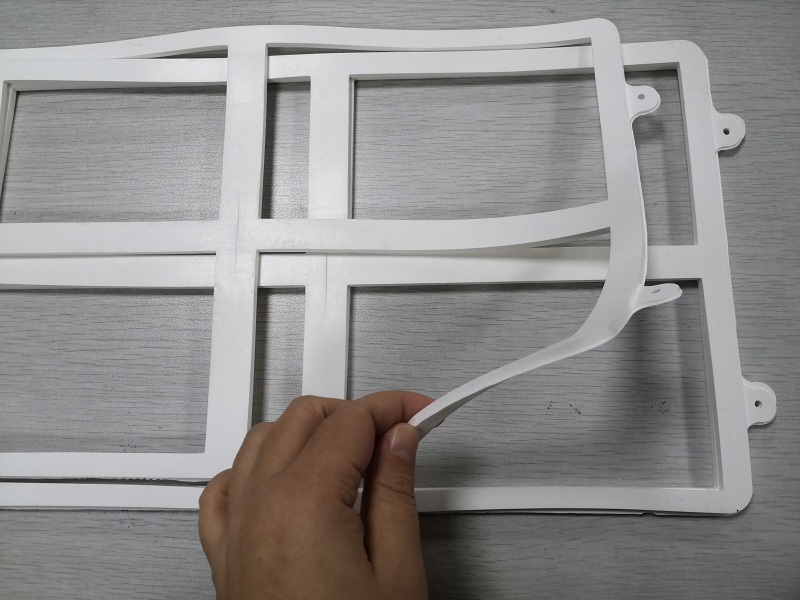

Guangdong Qin-Tech new energy thermal insulation cotton automatic assembly machine, the production process is to insert the aerogel into the four inner cavities of the silicone frame, put a PE film on the front and back of the assembly, into the pressing equipment, complete the assembly and automatic loading and unloading action. The pressing time with hot press is 15-20 seconds, which can save labor and improve productivity.

Equipment Introduction:

Process flow:

上一页

下一页

|