PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

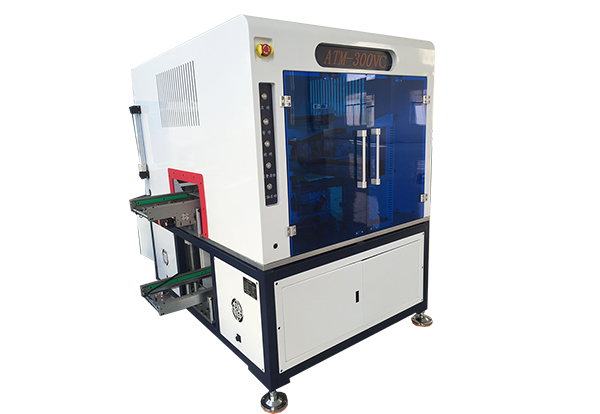

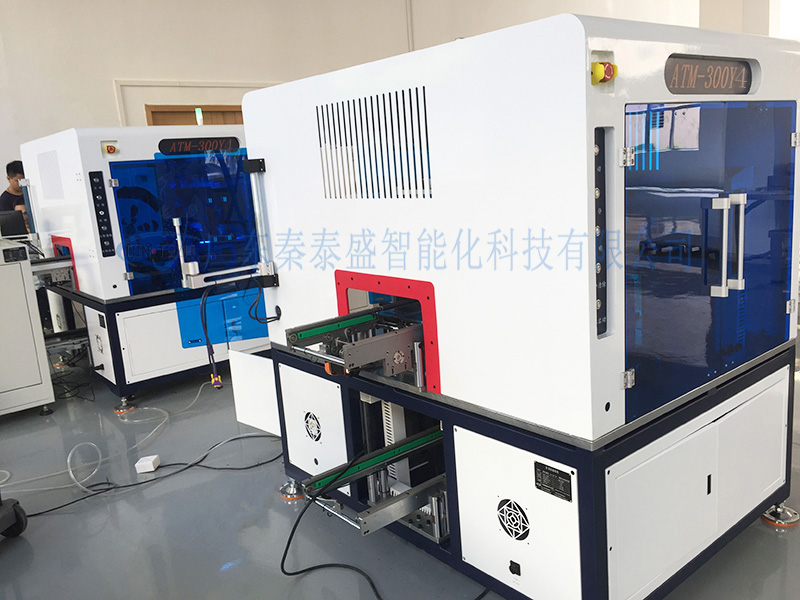

Model: ATM-300VC Configuration: Two placement heads; Up to four feeders can be hung

Function: ATM-300VC zero-sensing vapor chamber heat sink automatic adhesive sticking machine is a high-end machine customized by our company according to customer requirements. Adhesive, fast replacement of product models, high precision and efficiency, small footprint, simple equipment operation, and a customer quality traceability system can be established to improve product efficiency and quality.

Features: ●It can be customized with the reflow function of the vehicle, which occupies a small space and can operate one line by one person; ●It can realize the free combination of multiple machines for splicing and connection production, and can also be produced by a single machine; Diversity: According to different product sizes of customers, various models and sizes of machines are available for customers to choose, to meet the automatic production of motherboards or carriers with a maximum size of 300*350mm; ●Convenience: The structure of quick-release vacuum suction nozzle and quick-release feeder can quickly replace the suction nozzle and material according to the shape and size of the product, which greatly saves the time of changing the line; ●Easy operation: simplified and intuitive operation software, can quickly set and adjust the machine operation program, the old model can be switched to the line within five minutes, and it has the function of veneer and jigsaw sticking and SKIP; ●The whole system is equipped with high-resolution CCD, high-speed imaging vision system and stable vision module, which can quickly set template recognition for materials of different shapes to ensure the placement accuracy of high-speed production; ●Using linear motors to enhance stability, improve efficiency and ensure placement accuracy; ●Code reading: The vision system supports one-dimensional code and two-dimensional code reading, and is connected with the MES system to realize online production.

|