PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

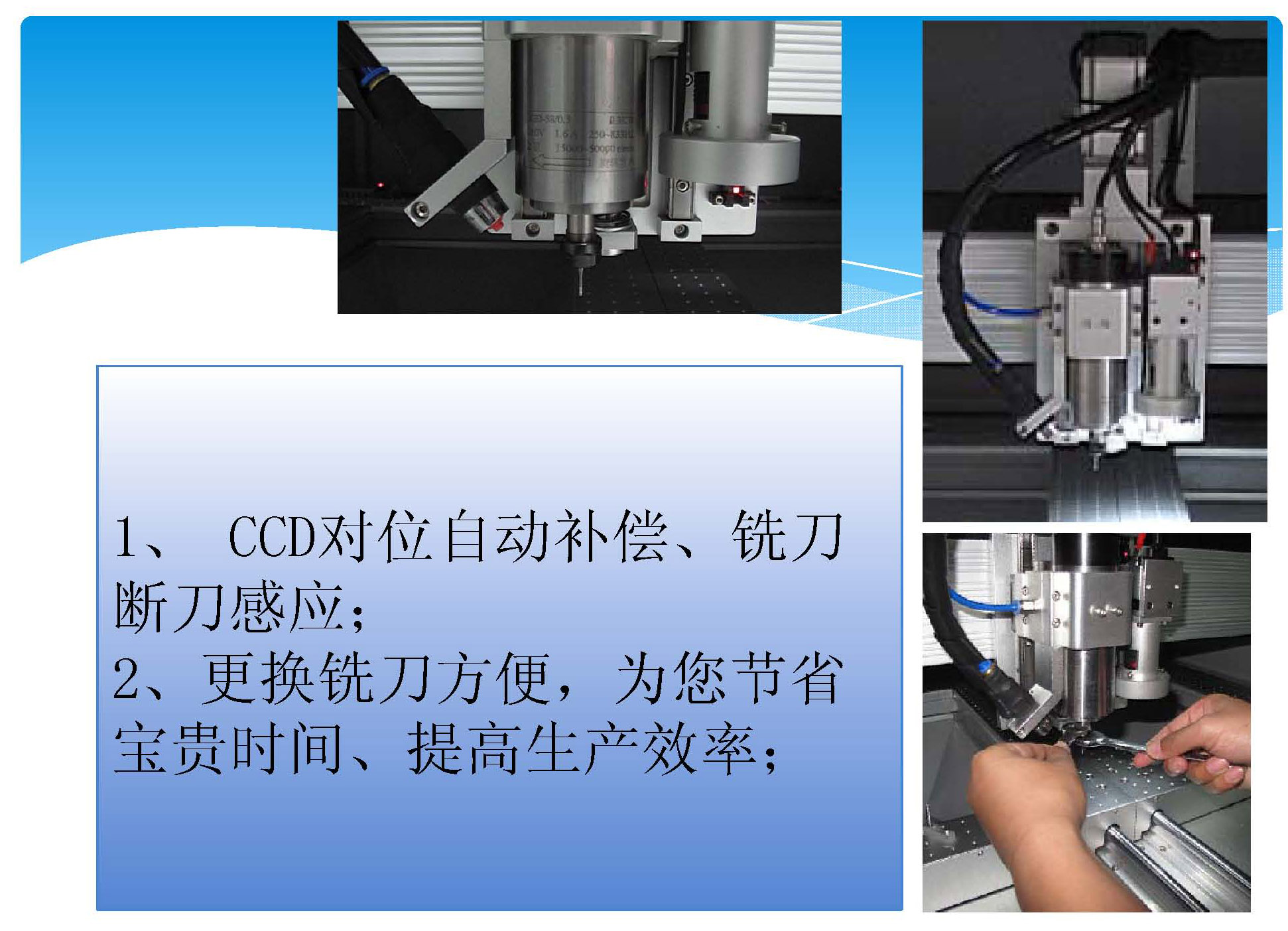

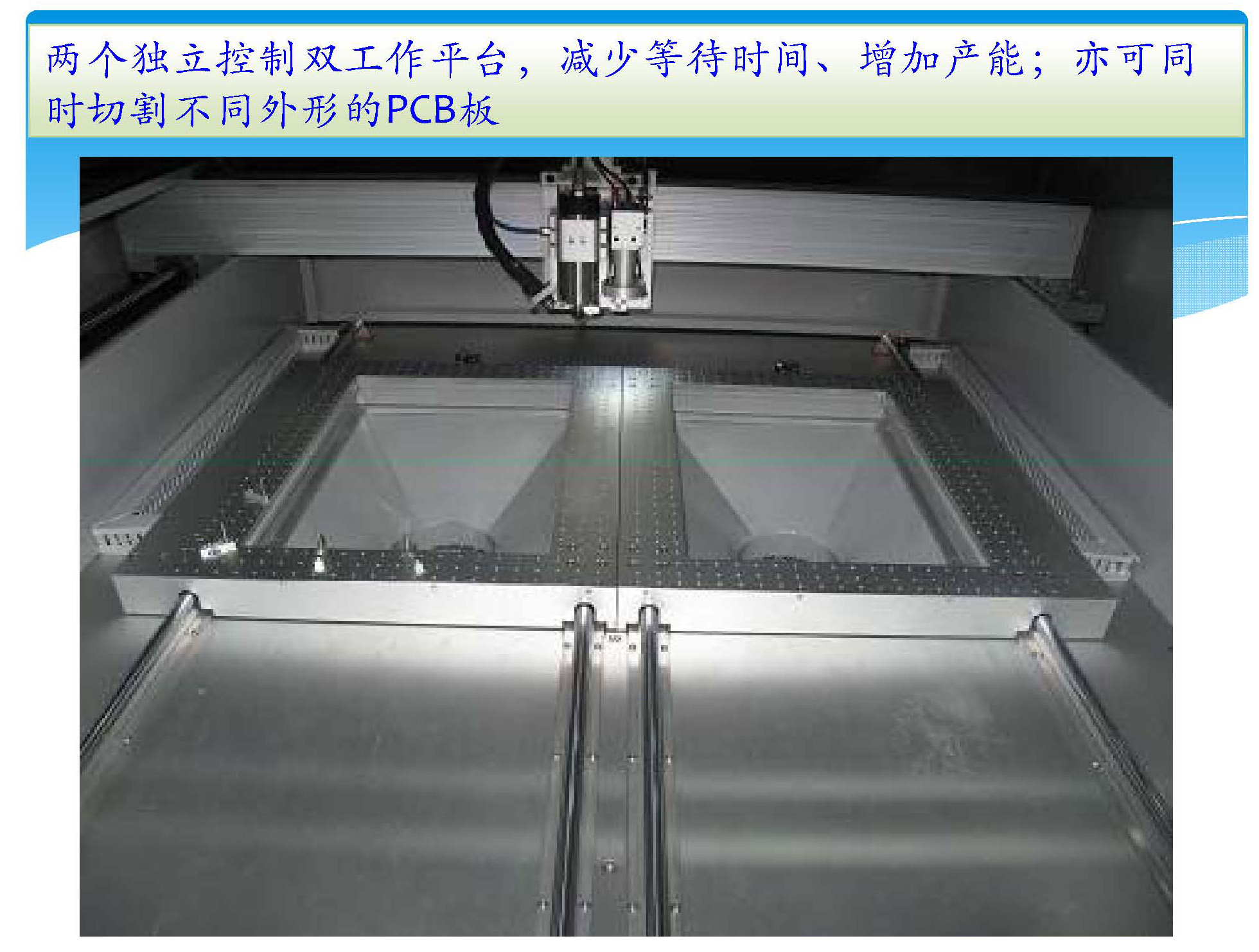

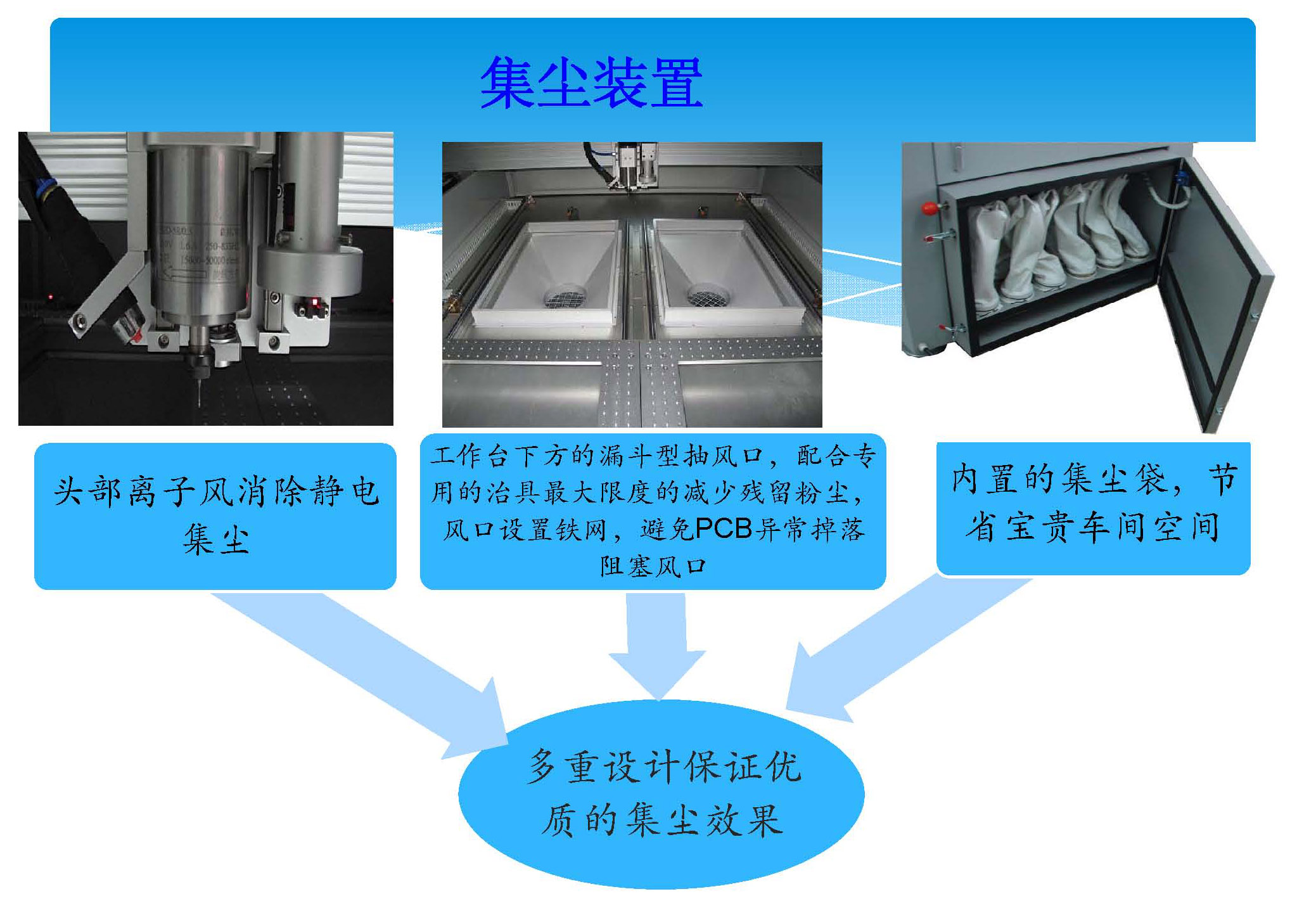

IT-951 series visual alignment automatic splitter is designed according to the cutting principle of high-speed motorized spindle without stress milling cutter, high-speed CCD visual automatic correction system, dual-platform feeding, one button can automatically complete Mark search and automatic offset compensation , Milling cutter cutting process. The computer control system specially tailored for SMT and SMD production workshops, with intuitive and simple programming steps and simple operation, can quickly improve product quality and production efficiency.

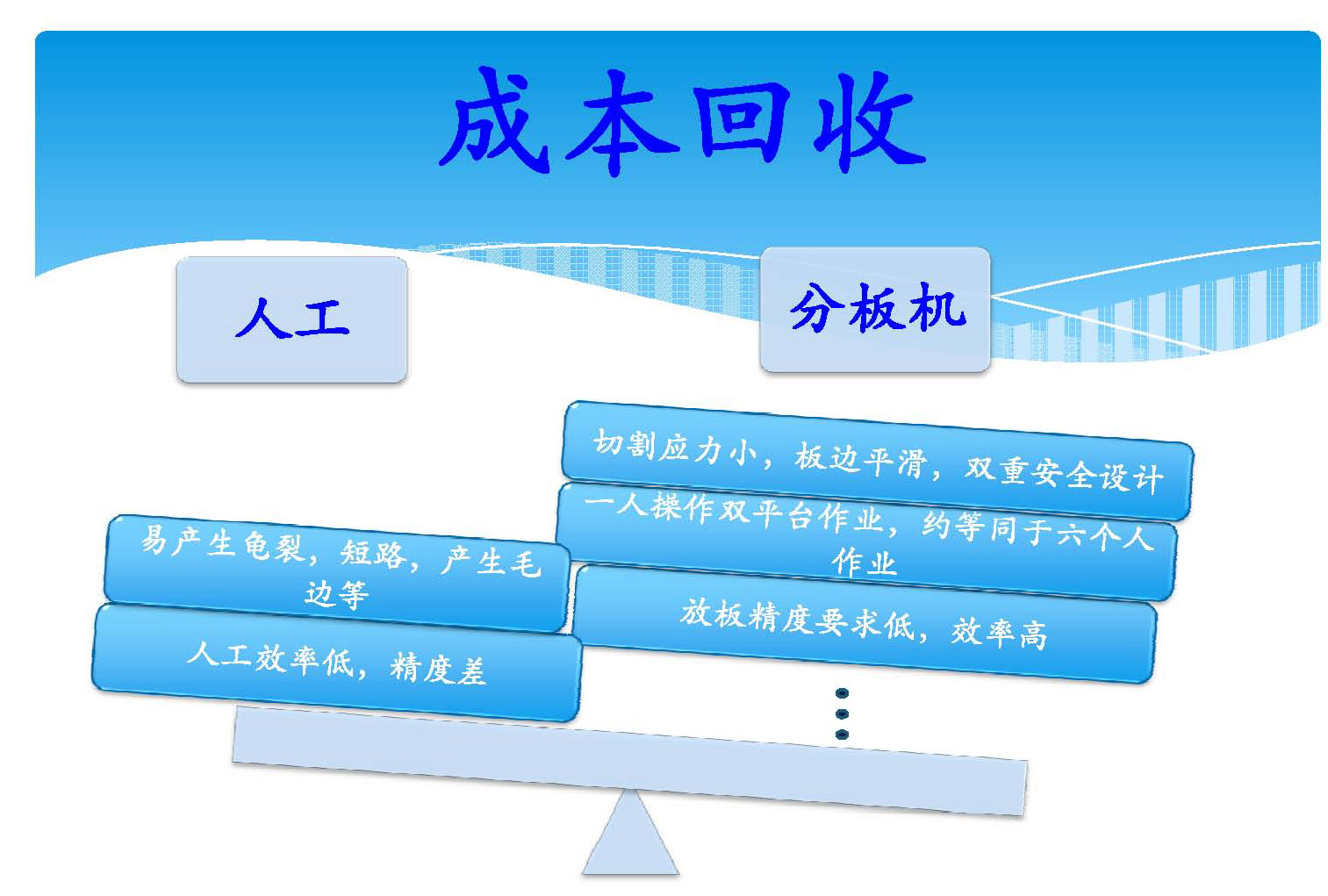

1. Iconized window operation screen, easy to learn and use 2. The processing file is generated by the method of teaching point collection, and single-step debugging can be carried out. 3. The left and right workbenches of the program can be copied, displayed, multi-angle connection board copy, single-step tracking modification function, block editing modification function, which accurately simplifies the time of program production and improves the editing efficiency. 4. Visual deviation correction Mark point recognition, path automatic deviation correction function. 5. Humanized operation: pre-display the path pattern, dynamic tracking and display of the processing process, manual intervention in the processing process (pause, resume, return to work zero, etc., emergency stop, etc.) 6. After the program is completed, an analogy test can be performed to check whether the path is correct; 7. After pressing the start function, the software will pop up a dialog box of "Have the path been compared?" to prompt the user to detect the cutting path, which greatly reduces the risk of novice cutting the PCB board. Cutting the maximum PCB size can be customized according to customer requirements.

上一页

|