PRODUCTS产品中心公司电话:0769-8166 4889 |

产品详情

当前位置:

首页>

产品详情

全国服务热线:0769-81664889

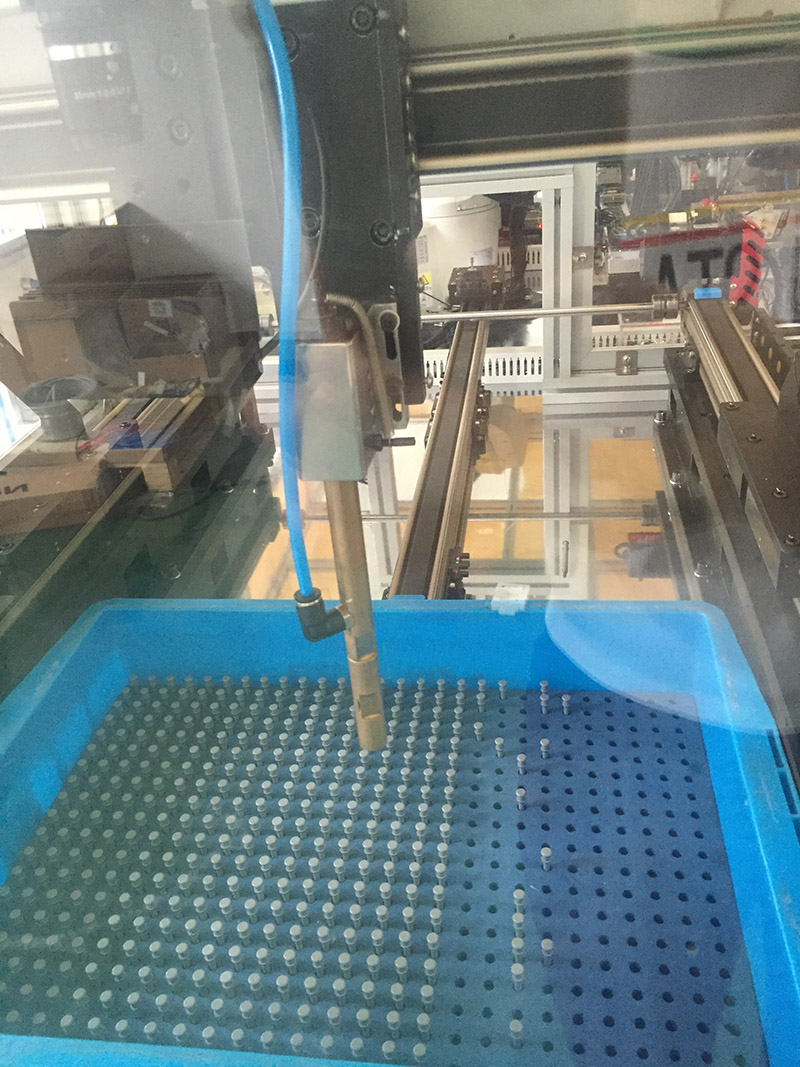

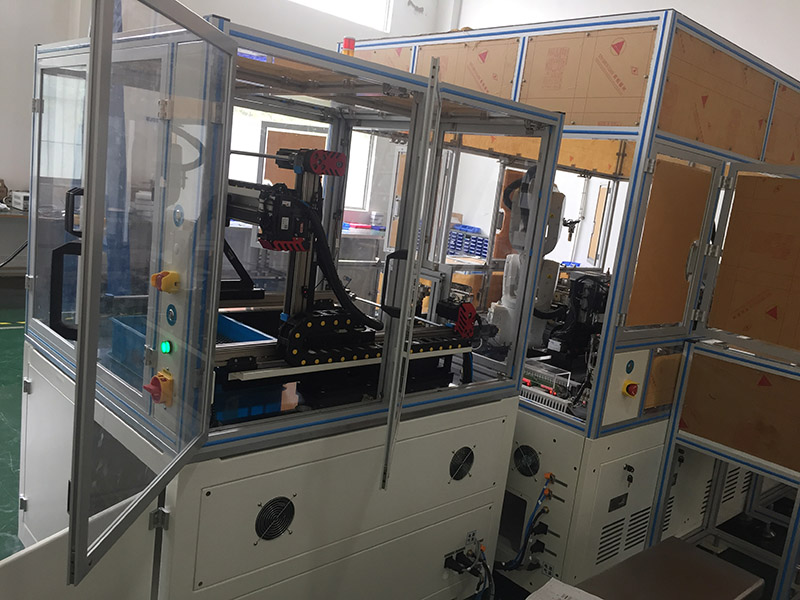

Product introduction Fully automatic pressure rod assembly equipment is a high-efficiency, fully automatic, pressure rod assembly assembly equipment independently developed and produced by our company according to customer requirements. This equipment has the ability to fully automatically produce 65 pressure rod assembly assemblies. Line function, the equipment should be safe and reliable, easy to operate, and the noise should meet the national first-class standard. There are a total of 10 kinds of materials in this product. In terms of hardware requirements, we are 100% OK in terms of incoming materials, including pressure rods, rosette rings, long cap rings, compression springs, non-standard gaskets and open retaining rings. These 6 kinds of materials are rigid objects, and the incoming materials and appearance are guaranteed to be qualified. The remaining rosette ring O-rings, long cap ring O-rings, star-shaped rings and rubber seats are not easy to distinguish in terms of incoming materials and appearance, and may be unqualified in subsequent assembly or due to other factors during equipment operation. Factors cause unqualified phenomena, so the equipment is mainly monitored for these conditions during operation.

配置说明

六轴机器人

CCD视觉取料

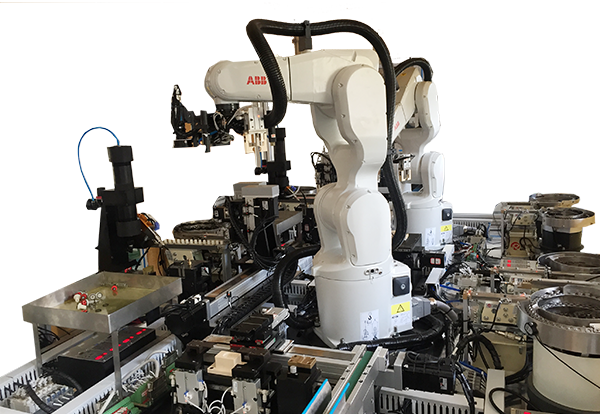

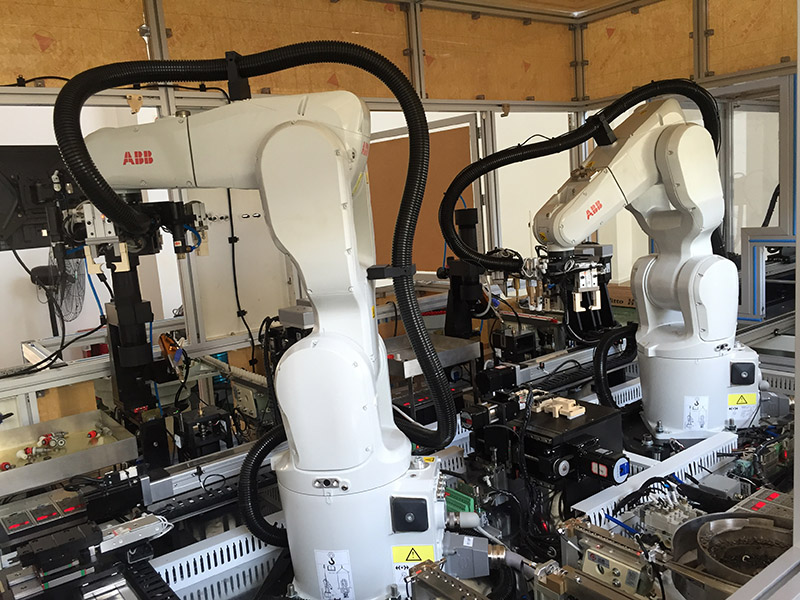

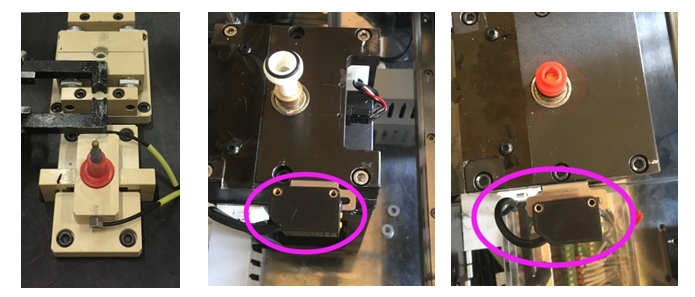

Multi-axis linear module The automated production line is designed by two 6-axis robots, a press-bar component feeder, 9 vibrating discs, 5 sets of modules, 4 sets of multi-axis linear modules, and three sets of CCD vision. Robots, loading and unloading modules and vibrating plates effectively assemble 10 kinds of materials together. Three sets of vision systems monitor components, semi-finished products and finished products to prevent wrong and missing installation. Software with independent software copyrights monitors the entire production and Real-time docking with the customer's MES system to achieve quality control and traceability. Press rod assembly machine - sensor

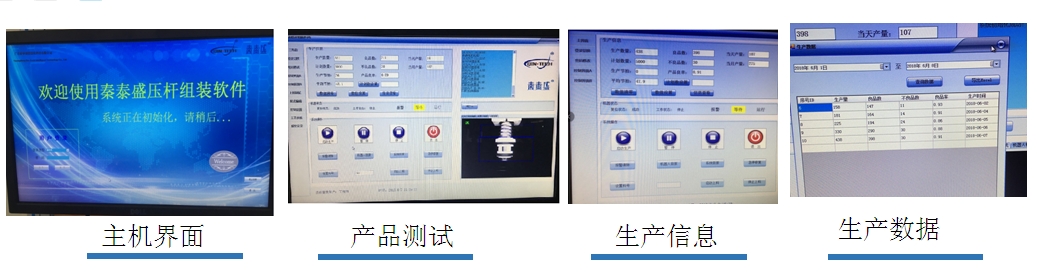

All materials are sent out with sensor judgment to avoid abnormal assembly and improve the stability of equipment and product quality. Software description Self-developed software

The software with independent software copyright monitors the entire production and connects with the customer's MES system in real time to achieve quality control and traceability. The self-developed software can add new functions in line with the actual needs of the customer's production line, optimize the program more flexibly, and be closer to some operating habits, improving the user's operating experience in the software. Technical Parameter

上一页

下一页

|