NEWS新闻资讯

电话:0769-81664889 传真:0769-85356530 邮箱:sales11@in-techgroup.com 地址:东莞市长安镇咸西社区莲湖路6号

|

新闻详情

当前位置:

首页>

新闻详情

Qin-Tech Waste Power Battery Secondary Utilization

专栏:Industry information

发布日期:2024-10-10

阅读量:834

收藏:

Qin-Tech Waste Power Battery Secondary Utilization: Reinventing the Precision Music of Green Energy Cycle

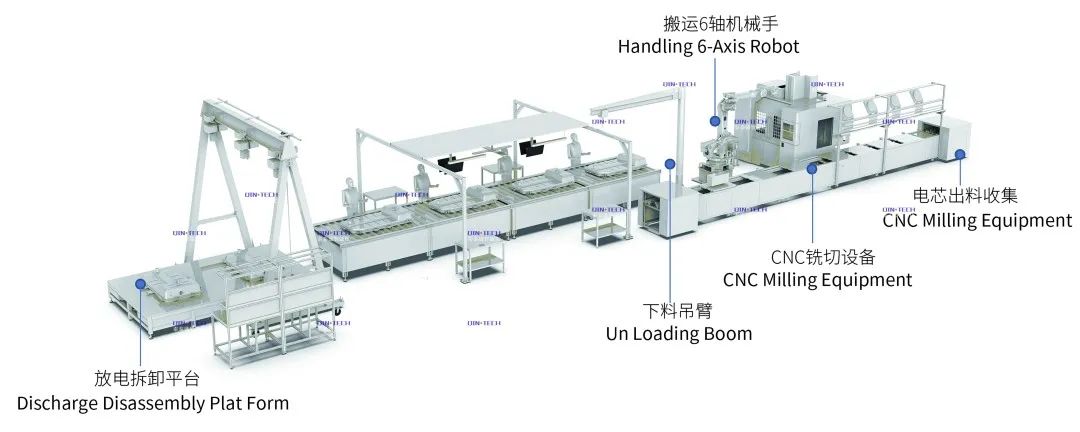

In the wave of booming development of the new energy vehicle industry, the treatment and reuse of used power batteries has become a dual topic of environment and resources that needs to be solved urgently. Qin-Tech's waste power battery secondary utilization project, especially its battery pack dismantling production line, is leading a profound change in this field with its unique innovative perspective and highly automated technical solutions. In this article, we will analyze several highlights of Qin-Tech's dismantling production line, and discuss how it can accurately meet the market demand and realize a new leap in green circular economy.

I. Eclecticism: the art of dismantling across car models In the field of power battery dismantling, Qin-Tech has shown unprecedented inclusiveness. Its dismantling production line can be compatible with chassis battery packs and even general modules from SUVs and cars to large buses and vans, which is undoubtedly a precise grasp of the diversity of the market. Imagine, whether it is an electric car shuttling through the city streets or a long-distance bus, their “heart” - used battery packs - can find a home in this production line. This wide compatibility not only reduces the cost of handling battery packs of different specifications but also greatly improves the efficiency of resource recycling, laying a solid foundation for building a comprehensive battery recycling system.

II. Intelligent speed regulation: the art of accurately matching material demand Another highlight of Qin-Tech's dismantling production line lies in its servo program-controlled speed regulation function. This technology, like an experienced craftsman, can flexibly adjust the running speed of the production line according to the speed-beat requirements of different materials. Whether dealing with heavyweight large battery packs or fine module units, the production line can operate at an optimized speed, ensuring dismantling efficiency and avoiding damages caused by speed mismatch. This intelligent speed regulation mechanism not only enhances the flexibility of the production line but also ensures the safety and stability of the dismantling process, which is a model of the perfect combination of technology and efficiency.

III. Frequency conversion conveying: low speed adjustable, the art of precise control The introduction of a variable frequency conveying system pushes the precise control of the Qin-Tech dismantling production line to a new height. The system allows the conveying speed to be adjustable within a wide range, and even low-speed adjustable stopping can be realized, providing unlimited possibilities for fine dismantling operations. During the disassembly process, certain parts or materials may need to be handled with special care, and adjusting the conveyor speed to the lowest possible level, or even stopping it temporarily, ensures that the operator has enough time to perform precise operations and avoid any possible damage. This kind of meticulous control is the key to making Qin-Tech's dismantling production line stand out in the industry.

IV. A high degree of automation: the art of reducing labor and increasing efficiency Increased automation is an important trend in modern industrial production, and Qin-Tech's dismantling production line is no exception. In this production line, manual involvement is greatly reduced and replaced by highly efficient and accurate automated equipment. From the initial positioning of the battery packs, cutting and separation, to the subsequent classification and recycling, the entire process is almost fully automated. This not only greatly improves production efficiency and reduces labor costs, but also reduces errors and safety hazards caused by human factors. The highly automated production mode makes Qin-Tech at the forefront of the field of secondary utilization of waste power batteries. Also, it sets a benchmark for the future development of the industry.

V. Green Cycle, Creating the Future Together Qin-Tech's waste power battery secondary utilization project, especially the successful practice of its battery pack disassembly production line, is not only a revolutionary breakthrough in the traditional disassembly method but also a vivid interpretation of the concept of the green circular economy. Through its inclusive design, intelligent speed regulation technology, precise control of inverter conveyors,s and highly automated production mode, Qin-Tech is gradually building an efficient, safe, and environmentally friendly battery recycling and utilization system. In this system, waste power batteries are no longer a burden to the environment but are transformed into valuable resources that promote the sustainable development of society. In the future, with the continuous progress of technology and the increasing maturity of the market, we have every reason to believe that Qin-Tech will continue to lead the new trend of the secondary utilization of waste power batteries and contribute to the construction of a greener, low-carbon world.

|